メールフォーマットエラー

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

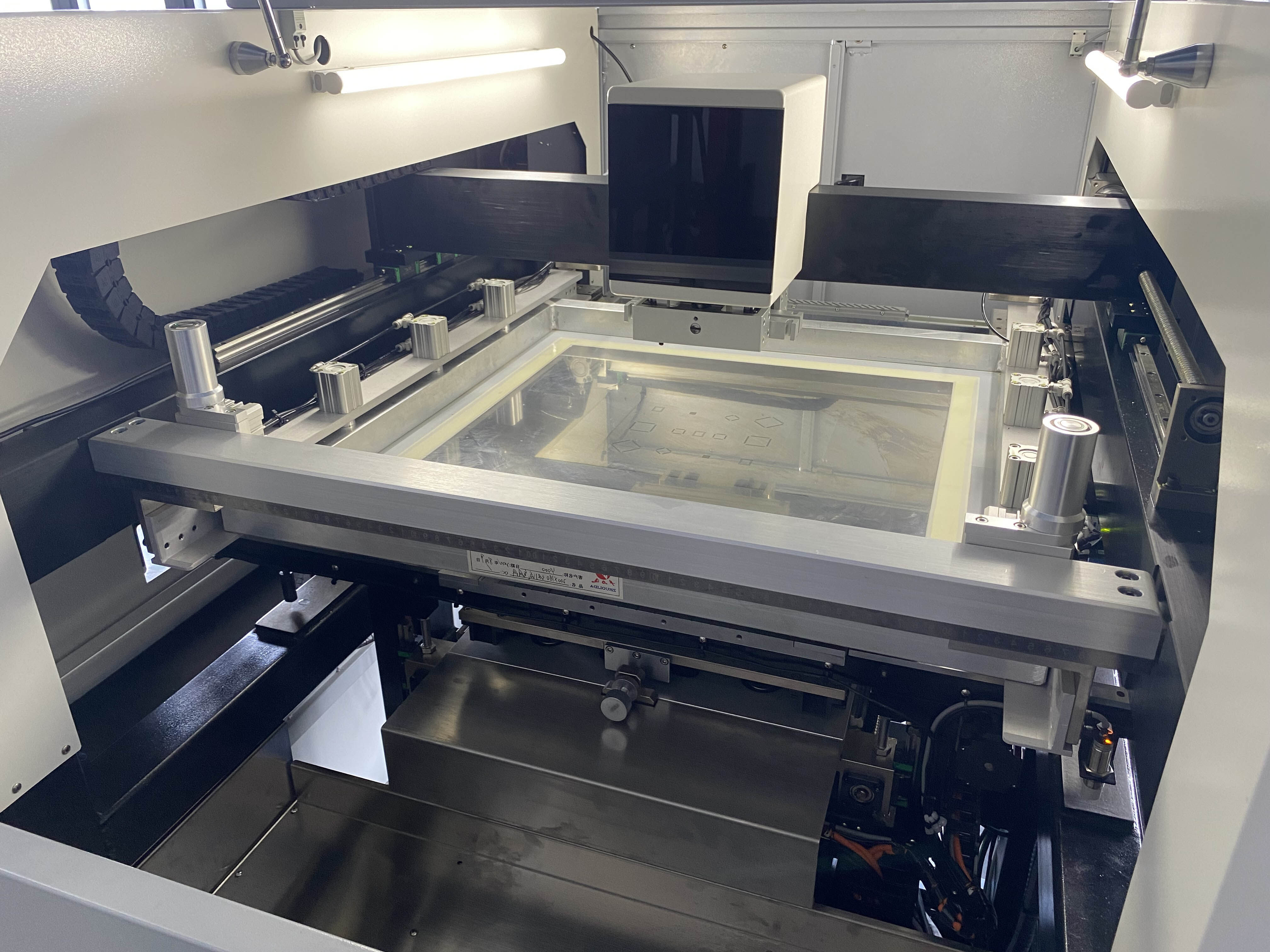

Choosing the Right Solder Paste Stencil Printer for Your Electronics Manufacturing Project

Solder paste stencil printers are an essential tool in the electronics industry, providing a cost-effective and efficient method for applying solder paste to printed circuit boards (PCBs). There are several types of solder paste stencil printers available, including manual, semi-automatic, and fully automatic machines. Each type of machine has its own advantages and disadvantages, and choosing the right one for your project is critical to ensuring accurate and consistent application of solder paste.

Manual solder paste stencil printers are the most basic type of stencil printer. They consist of a frame, a stencil holder, and a squeegee, and are operated manually by the operator. These printers are typically less expensive than their automated counterparts, making them an ideal choice for small businesses or hobbyists. The manual operation allows for greater control and precision, ensuring that the solder paste is applied accurately and consistently. However, manual machines can be time-consuming and may not be suitable for large-scale production.

Semi-automatic solder paste stencil printers are a step up from manual printers. They typically include a motorized stencil frame, which allows for more precise alignment of the stencil with the PCB. The solder paste is still applied manually, but the motorized frame makes the process faster and more efficient. Semi-automatic machines are ideal for medium-scale production, where speed and precision are important.

Fully automatic solder paste stencil printers are the most advanced type of stencil printer. They are designed to be fully automated, with the solder paste application process controlled by a computer. These machines are typically used in high-volume production environments, where speed and efficiency are critical. Fully automatic machines are the most expensive type of stencil printer, but they offer the highest level of precision and control.

When choosing a solder paste stencil printer, it is important to consider the specific needs of your project. Factors to consider include the size and complexity of the PCB, the volume of production, and the level of precision and control required. Additionally, the cost of the machine should be taken into consideration, as well as the level of expertise required to operate the machine.

In conclusion, solder paste stencil printers are an essential tool for electronics manufacturing projects. Choosing the right type of machine is critical to ensuring accurate and consistent application of solder paste. Manual machines are ideal for small-scale projects, while semi-automatic and fully automatic machines are better suited for larger-scale production. With the right machine, you can ensure high-quality electronic products that meet your specific needs.