メールフォーマットエラー

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Decoding Costs: Automated Industrial Wave Soldering Machine Price Insights

Introduction

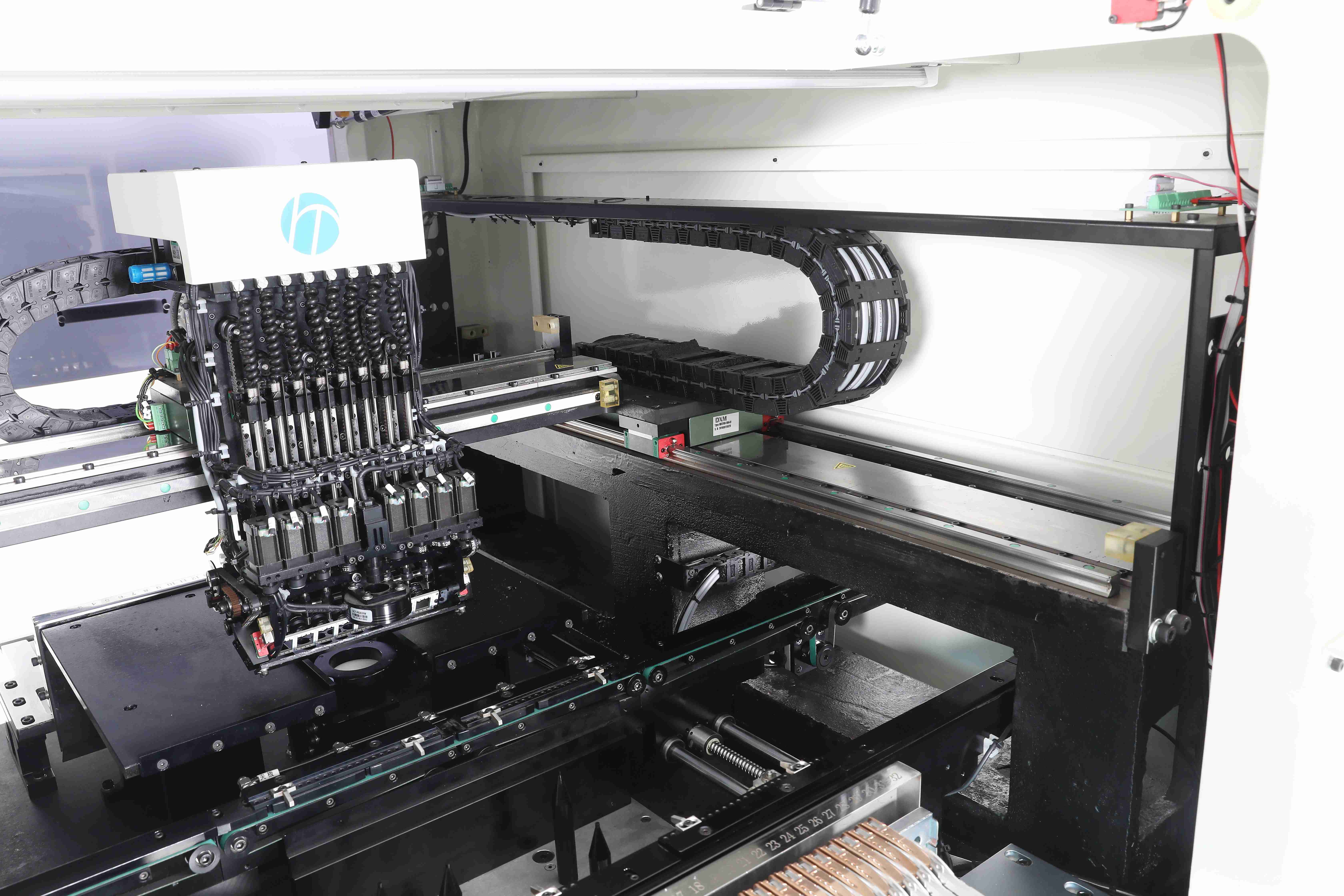

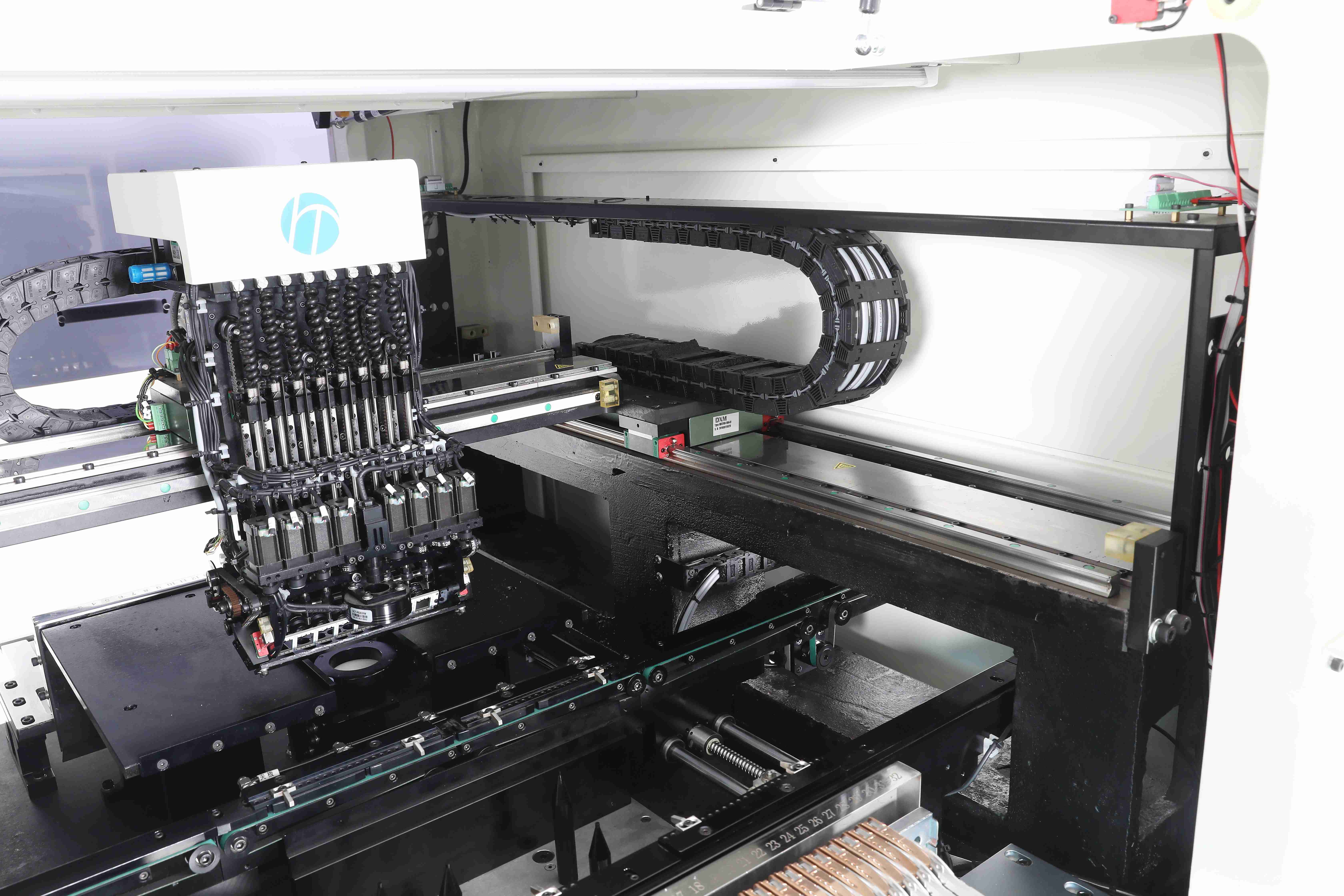

In the ever-evolving landscape of industrial manufacturing, the demand for efficient and cost-effective solutions has fueled the exploration of automated industrial wave soldering machines. Today, we delve into the realm of these sophisticated machines and unravel the crucial factor that often tips the scales in favour of businesses: the automated industrial wave soldering machine price.

Understanding the Significance of Automated Industrial Wave Soldering Machines

Automated industrial wave soldering machines play a pivotal role in electronics manufacturing, seamlessly soldering electronic components onto printed circuit boards (PCBs). Their significance lies not just in the precision of the soldering process but also in their potential to streamline production and reduce labour costs. For businesses eyeing advancements in automation, these machines stand as technological marvels.

Factors Influencing Automated Industrial Wave Soldering Machine Prices

When navigating the market for automated industrial wave soldering machines, businesses encounter a myriad of factors influencing the price spectrum. From the intricacies of the soldering process to the overall machine efficiency, each element contributes to the final automated industrial wave soldering machine price tag.

Balancing Affordability and Quality in Automated Industrial Wave Soldering Machines

While cost remains a crucial consideration, it is imperative to strike a balance between affordability and quality. Investing in a machine solely based on a low automated industrial wave soldering machine price may lead to compromises in terms of durability, performance, and long-term reliability. It's essential for businesses to assess their specific production needs and find a machine that aligns with both budget constraints and quality requirements.

The Technological Landscape: A Synthesis of Automation and Precision

From a technological perspective, the integration of automation in wave soldering machines represents a significant leap forward. These machines leverage advanced control systems, precise solder nozzle technologies, and innovative conveyor systems. As the industry moves towards smart manufacturing, the automated industrial wave soldering machine price reflects the investments made in cutting-edge technologies that enhance efficiency and reduce error margins.

Market Dynamics and Competitive Pricing Strategies

In the competitive market for automated industrial wave soldering machines, manufacturers employ various pricing strategies to gain a competitive edge. Some focus on providing cost-effective solutions for startups and small enterprises, while others position their machines as high-end, targeting larger corporations with advanced production needs. Understanding these market dynamics is crucial for businesses aiming to make informed decisions based on their unique requirements.

Cross-Industry Applications: Insights from Diverse Sectors

The utility of automated industrial wave soldering machines extends beyond traditional electronics manufacturing. Industries ranging from automotive to aerospace and medical devices leverage these machines for their soldering needs. Exploring cross-industry applications provides a comprehensive understanding of the diverse factors influencing the price of automated industrial wave soldering machines in various sectors.

Navigating the Supplier Landscape: Finding Value in Affordability

When seeking automated industrial wave soldering machines, businesses are confronted with a multitude of suppliers. Navigating this landscape requires a discerning eye to identify reliable suppliers offering competitive prices without compromising on quality. It's crucial to delve into customer reviews, supplier certifications, and warranty terms to ensure a seamless partnership.

Conclusion

In conclusion, the automated industrial wave soldering machine price encapsulates a complex interplay of technological advancements, market dynamics, and the diverse needs of industries. Striking the right balance between affordability and quality is not just a financial consideration but a strategic investment in the future of efficient and precise electronics manufacturing. As businesses embark on this journey, a nuanced understanding of the factors influencing prices will pave the way for informed decisions and sustainable growth.