メールフォーマットエラー

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

How SMT Stencil Machines Can Improve Your Production Efficiency?

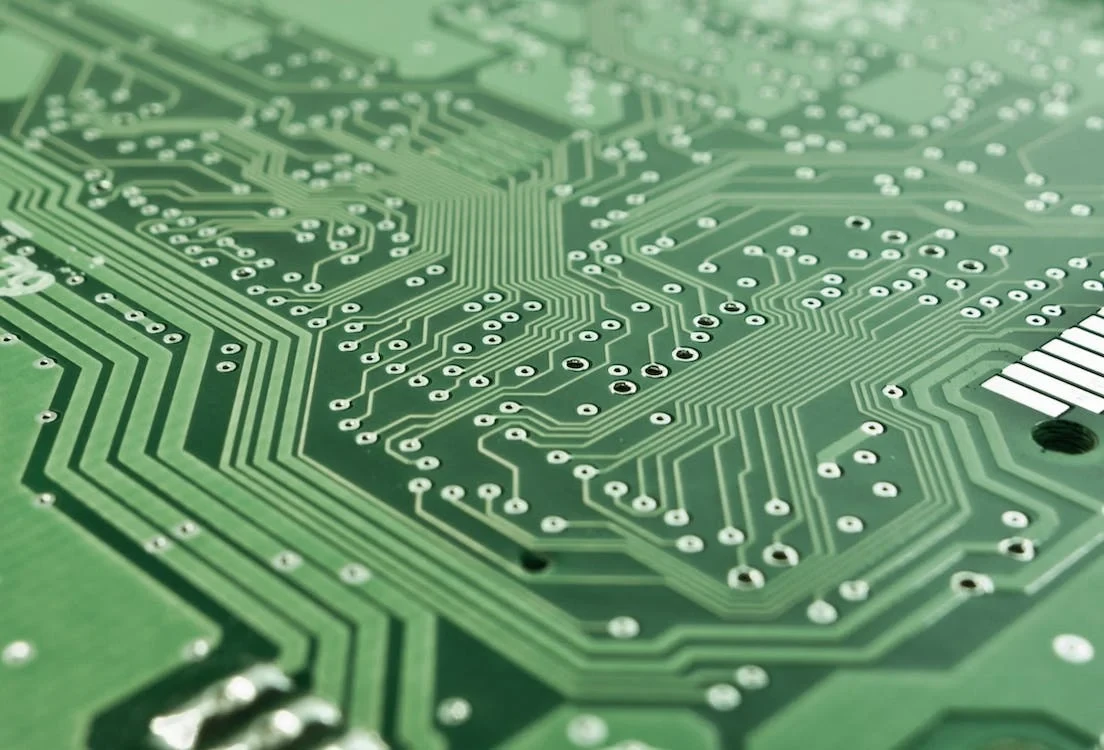

In today's fast-paced manufacturing industry, staying ahead of the competition requires constant innovation and finding ways to improve production efficiency. One such tool that has proven to be invaluable in the surface mount technology (SMT) process is the SMT stencil machine. This article explores the benefits of using these machines and how they can significantly enhance your production efficiency.

I. Understanding SMT Stencil Machines

SMT stencil machines are precision tools used in the SMT assembly process to apply solder paste onto circuit boards. They consist of a metal stencil, typically made of stainless steel, with apertures that match the solder paste patterns on the PCB. These machines allow for accurate and consistent application of solder paste, reducing the risk of defects and improving overall production quality.

II. Streamlining the Production Process

1. Enhanced Accuracy and Consistency:

Wholesale SMT stencil machines play a crucial role in achieving high accuracy and consistency during the solder paste application. The precisely cut apertures on the stencil ensure that the right amount of solder paste is deposited onto each pad, minimizing the likelihood of soldering defects. This level of precision is difficult to achieve manually, making stencil machines indispensable in large-scale production.

2. Time Efficiency:

By automating the solder paste application process, SMT stencil machines save significant time compared to manual methods. These machines can swiftly apply solder paste to multiple PCBs simultaneously, reducing assembly time and increasing production throughput. The time saved can be utilized for other critical tasks, such as quality control and testing, resulting in a more streamlined manufacturing process.

III. Improving Overall Production Quality

1. Reduction in Defects:

The accurate and consistent application of solder paste achieved through SMT stencil machines minimizes the occurrence of defects, such as solder bridges or insufficient solder joints. This leads to improved product quality and reliability, reducing the need for rework and increasing customer satisfaction.

2. Consistent Solder Volume:

One of the key advantages of SMT stencil machines is their ability to control the volume of solder paste applied to each pad consistently. Maintaining a consistent solder volume is crucial for achieving proper solder joints, as it ensures reliable electrical connections and thermal performance. Wholesale SMT stencil machines allow for precise control over solder paste deposition, contributing to consistent and reliable solder joints across the entire PCB assembly.

IV. Cost-Effectiveness and Scalability

1. Cost Savings:

While the initial investment in an SMT stencil machine may seem significant, it offers long-term cost savings. The reduction in defects and rework translates to lower production costs and improved overall yield. Additionally, the time saved through automation can be used to increase production capacity without requiring additional resources, leading to further cost efficiency.

2. Scalability:

SMT stencil machines are highly scalable, allowing manufacturers to adapt to varying production demands. Whether you're manufacturing small batches or high volumes, these machines can accommodate the changing needs of your production line. This scalability ensures that your manufacturing process remains efficient and flexible as your business grows.

Conclusion:

Wholesale SMT stencil machines are indispensable tools for enhancing production efficiency in the surface mount technology process. Their ability to provide accurate and consistent solder paste application, improve overall production quality, and offer cost-effectiveness and scalability make them a valuable asset for any manufacturing operation. By incorporating SMT stencil machines into your production line, you can achieve higher productivity, reduced defects, and improved customer satisfaction, ultimately giving your business a competitive edge in the industry.