メールフォーマットエラー

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

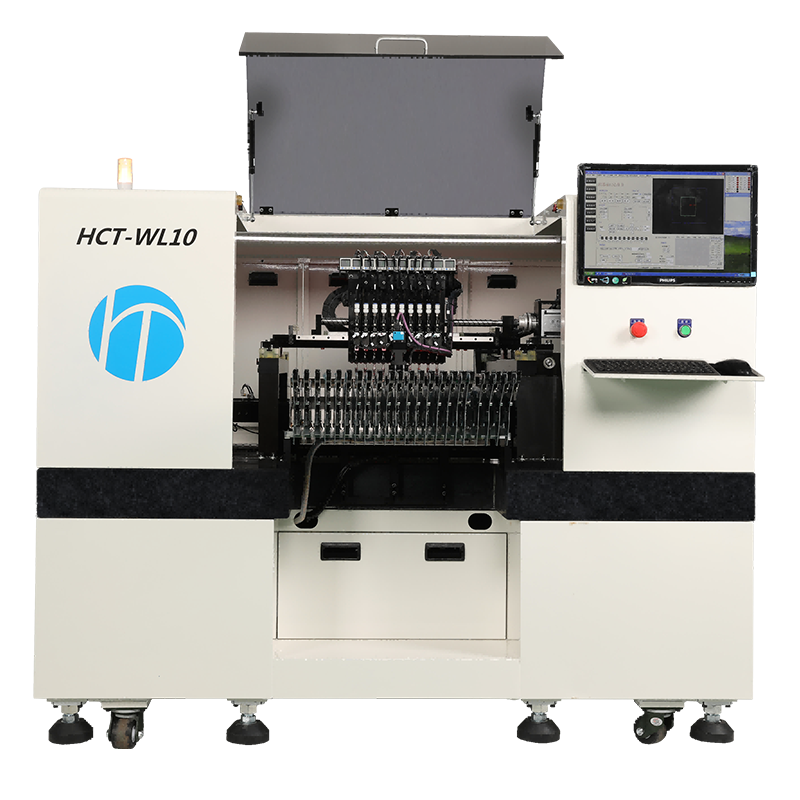

LED Placement Machine: Revolutionizing Electronics Manufacturing

The electronics manufacturing industry has seen tremendous advancements over the past few decades. One of the most significant innovations contributing to this progress is the LED placement machine. This sophisticated piece of equipment has streamlined the production process, increased efficiency, and improved the quality of electronic devices. In this blog, we'll delve into the world of LED placement machines, exploring their functionality, benefits, and impact on the industry.

What is an LED Placement Machine?

An LED placement machine, also known as an SMT (Surface Mount Technology) placement machine, is a robotic device used to place LEDs and other surface-mount components onto printed circuit boards (PCBs). These machines are integral to the automated assembly lines in electronics manufacturing. They ensure precise and rapid placement of tiny components, which is crucial for maintaining the high standards required in modern electronics.

The Mechanism Behind LED Placement Machines

LED placement machines operate using advanced technologies, including vision systems, robotics, and software algorithms. The process typically involves the following steps:

Component Feeding: Components are supplied to the machine through feeders or trays. Each feeder holds a specific type of component, and the machine can switch between feeders as needed.

Vision Inspection: Before placement, components are inspected using high-resolution cameras to ensure they are correctly oriented and free of defects.

Pick-and-Place: The machine's robotic arm picks up the component using a vacuum nozzle and places it onto the PCB with extreme precision. The placement coordinates are pre-programmed into the machine.

Soldering: After placement, the components are soldered onto the PCB using reflow soldering or other methods to secure them in place.

Types of LED Placement Machines

LED placement machines come in various types, each designed to cater to different manufacturing needs:

High-Speed Machines: These machines prioritize speed and are capable of placing thousands of components per hour. They are ideal for mass production environments where efficiency is paramount.

High-Precision Machines: Designed for applications where accuracy is critical, such as in medical devices or aerospace electronics, these machines offer exceptional precision at a slightly slower pace.

Multi-Functional Machines: These versatile machines can handle a wide range of components and are suitable for manufacturers with diverse product lines.

Benefits of Using LED Placement Machines

The adoption offers numerous advantages to electronics manufacturers:

Enhanced Precision and Accuracy

LED placement machines can place components with an accuracy of a few micrometers. This level of precision is essential for modern electronics, where even minor misalignments can affect the functionality and reliability of the final product.

Increased Production Speed

Automated placement significantly speeds up the assembly process. High-speed placement machines can handle thousands of components per hour, far surpassing the capabilities of manual assembly.

Cost Efficiency

While the initial investment can be substantial, the long-term cost savings are considerable. Automation reduces labor costs, minimizes waste due to human error, and improves overall production efficiency.

Consistent Quality

Automation ensures consistent quality across all units produced. LED placement machines adhere to strict programming, ensuring that each component is placed accurately and securely, which is critical for maintaining product reliability and customer satisfaction.

Flexibility and Scalability

Modern LED placement machines are highly adaptable and can be quickly reconfigured for different products. This flexibility is particularly beneficial for manufacturers who need to produce a variety of electronics. Additionally, the scalability of these machines allows companies to easily ramp up production in response to market demand.

Impact on the Electronics Industry

The introduction has had a profound impact on the electronics industry, driving innovation and efficiency. Let's explore some of the key areas where these machines have made a difference:

Consumer Electronics

In the consumer electronics sector, speed and precision are crucial due to the high demand and rapid product cycles. The placement machines have enabled manufacturers to produce smartphones, tablets, and other devices at an unprecedented pace, meeting market demand and pushing technological boundaries.

Automotive Industry

Modern vehicles are equipped with numerous electronic components, from infotainment systems to advanced driver-assistance systems (ADAS). LED placement machines ensure the reliable and precise assembly of these components, contributing to the safety and performance of vehicles.

Medical Devices

In the medical field, the reliability and precision of electronic devices can be a matter of life and death. LED placement machines are essential for producing high-quality medical equipment, such as diagnostic machines and wearable health monitors, ensuring they meet stringent regulatory standards.

Telecommunications

The telecommunications industry relies on high-performance electronic devices for infrastructure and consumer use. LED placement machines facilitate the production of complex PCBs required for routers, modems, and other networking equipment, supporting the global communications network.

Future Trends and Innovations

As technology continues to advance, the placement machines are also evolving. Here are some future trends and innovations to watch:

Artificial Intelligence and Machine Learning

Integrating AI and machine learning into LED placement machines can enhance their performance and adaptability. AI algorithms can optimize placement strategies, improve defect detection, and enable predictive maintenance, reducing downtime and increasing efficiency.

Enhanced Vision Systems

Advancements in vision systems will further improve the accuracy and reliability. High-resolution cameras and sophisticated image processing algorithms can detect even the smallest defects and ensure perfect component orientation.

Internet of Things (IoT) Integration

IoT integration allows LED placement machines to communicate with other equipment on the assembly line, enabling real-time data exchange and better coordination. This connectivity can lead to more efficient production processes and quicker responses to any issues that arise.

Miniaturization and Precision

As electronic devices continue to shrink in size, the demand for smaller components and higher precision placement will grow. Future LED placement machines will need to handle these tiny components with even greater accuracy and speed.

Sustainability and Energy Efficiency

The electronics industry is increasingly focusing on sustainability. Future LED placement machines will likely incorporate energy-efficient technologies and materials, reducing their environmental impact and contributing to greener manufacturing practices.

Challenges and Considerations

While LED placement machines offer numerous benefits, manufacturers must also consider some challenges:

Initial Investment

The cost of acquiring and setting up an LED placement machine can be high. Companies need to evaluate their production volume and long-term benefits to justify this investment.

Maintenance and Training

Proper maintenance is crucial for the optimal performance of LED placement machines. Additionally, operators and technicians need to be adequately trained to handle these sophisticated devices, which can involve a learning curve and additional costs.

Adaptability to New Technologies

The rapid pace of technological advancements means that LED placement machines must be adaptable to new components and assembly techniques. Manufacturers need to ensure their equipment can keep up with these changes to stay competitive.

Conclusion

The LED placement machine has undoubtedly revolutionized the electronics manufacturing industry. Its ability to enhance precision, increase production speed, and ensure consistent quality has made it an indispensable tool for manufacturers. As technology continues to evolve, these machines will become even more sophisticated, driving further innovations and efficiencies in the industry.

By understanding the capabilities and benefits of LED placement machines, manufacturers can make informed decisions about integrating them into their production lines. This investment not only boosts productivity but also positions companies to meet the ever-growing demands of the modern electronics market. As we look to the future, the continued development of LED placement machines will play a pivotal role in shaping the next generation of electronic devices.