メールフォーマットエラー

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

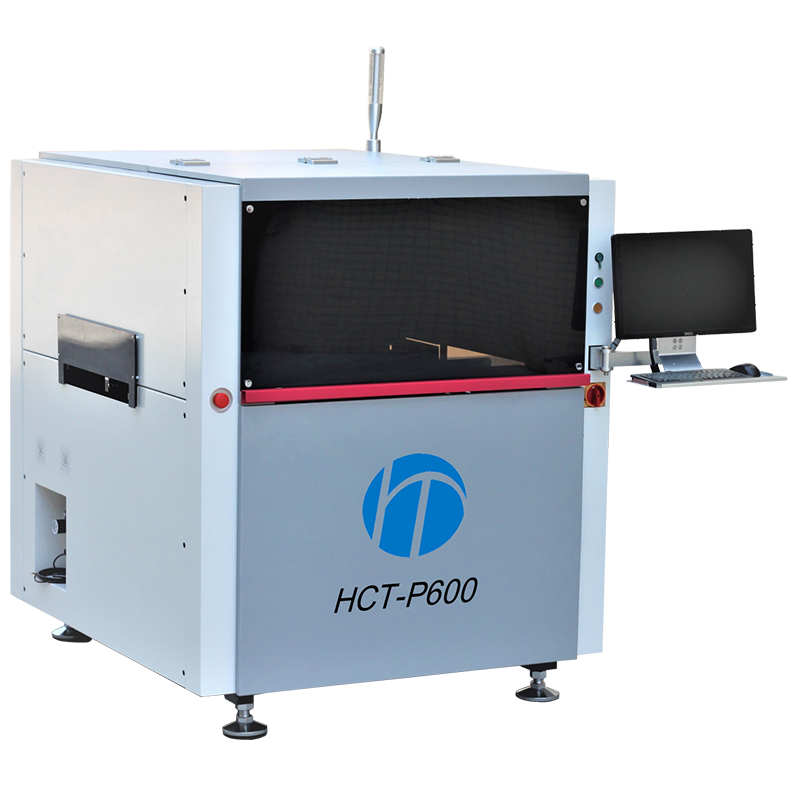

Maximizing Efficiency and Precision with a High-Accuracy Automatic Stencil Printer

Precision and efficiency are crucial in today's fast-paced manufacturing industry. To meet these demands, businesses require cutting-edge equipment that can streamline their production processes effectively. One such essential tool is the High Accuracy Automatic Stencil Printer. This blog post will delve into the features and benefits of this advanced printing solution, highlighting its ability to enhance accuracy, improve efficiency, and optimize overall productivity.

The Importance of High Accuracy Automatic Stencil Printers:

High Accuracy Automatic Stencil Printers play a crucial role in the electronics manufacturing industry. These printers ensure precise and consistent application of solder paste onto printed circuit boards (PCBs). By achieving accurate alignment and maintaining a high level of repeatability, these printers significantly reduce the risk of defects and enhance the overall quality of the PCB assembly process.

Unparalleled Precision:

With its cutting-edge technology, a High Accuracy Automatic Stencil Printer offers unparalleled precision. The printer’s advanced vision system detects fiducial marks on the PCB, allowing for precise alignment of the stencil. This ensures that the solder paste is applied accurately, even on complex PCB designs. The printer’s high-resolution printing capabilities guarantee that each solder paste deposit is precisely placed, minimizing the chances of bridging or insufficient solder.

Streamlined Efficiency:

Efficiency is a key factor in any manufacturing process. High Accuracy Automatic Stencil Printers excel in this aspect by automating the printing process, eliminating the need for manual intervention. These printers can handle large volumes of PCBs with ease, reducing production time and increasing throughput. By minimizing human error and optimizing the printing process, businesses can achieve higher productivity levels and meet tight deadlines.

Quick Setup and Changeover:

Time is of the essence in the manufacturing industry. High Accuracy Automatic Stencil Printers offer quick setup and changeover capabilities, allowing for seamless transitions between different PCB designs. With intuitive software interfaces and automated stencil alignment, these printers significantly reduce the time required for setup and changeover, ensuring minimal downtime and maximizing production efficiency.

Enhanced Quality Control:

Maintaining consistent quality is crucial for any manufacturing operation. High Accuracy Automatic Stencil Printers incorporate advanced inspection systems that verify the accuracy of each solder paste deposit. By detecting defects such as insufficient solder or misalignment, these printers enable real-time quality control, reducing the risk of faulty PCB assemblies. This ensures that only high-quality products reach the market, enhancing customer satisfaction and brand reputation.

Cost Savings:

Investing in a High Accuracy Automatic Stencil Printer can lead to significant cost savings in the long run. By minimizing defects and rework, businesses can reduce material waste and labor costs. Additionally, the printer’s high-speed printing capabilities and streamlined processes optimize resource utilization, further enhancing cost-effectiveness.

Conclusion:

In the competitive world of electronics manufacturing, a High Accuracy Automatic Stencil Printer is an indispensable tool for achieving precision, efficiency, and productivity. By leveraging advanced technology and automation, these printers ensure accurate solder paste application, streamline processes, and enhance overall quality control. Investing in a High Accuracy Automatic Stencil Printer is a strategic move that can propel businesses towards success in the ever-evolving manufacturing landscape.