メールフォーマットエラー

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

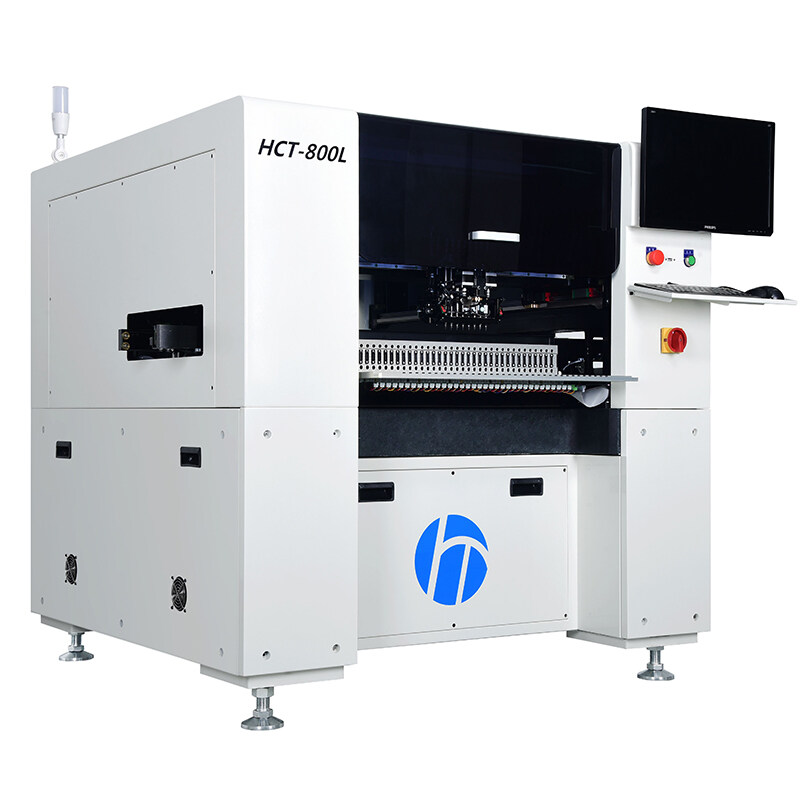

Multifunctional SMT Pick and Place Machines

In the fast-paced world of electronics manufacturing, where innovation is the key to staying ahead, the multifunctional SMT pick and place machine has emerged as a silent hero. These machines are not just tools; they are the backbone of precision, efficiency, and innovation in the production line. Whether you're an electronics enthusiast, a seasoned engineer, or a business owner looking to streamline your operations, the impact of these machines is undeniable. Let's explore the world of multifunctional SMT pick-and-place machines and understand why they are essential in today's manufacturing landscape.

The Evolution of Electronics Assembly:

The journey from manual assembly to automated precision has been a remarkable one. As technology advances, so does the demand for smaller, more complex, and higher-performance electronic devices. This evolution has led to the development of multifunctional SMT pick and place machines, which have revolutionized the surface-mount technology (SMT) assembly process.

What Are Multifunctional SMT Pick and Place Machines?

At their core, multifunctional SMT pick and place machines are automated devices designed to accurately place surface-mount components onto printed circuit boards (PCBs). These machines are equipped with advanced features that allow them to handle a variety of components, from small passives to large ICs, with high precision and speed. The term "multifunctional" refers to their ability to perform multiple tasks, such as component recognition, placement, and even reflow soldering, all in one integrated system.

Key Benefits of Multifunctional SMT Pick and Place Machines:

Enhanced Precision and Speed:

One of the most significant advantages of multifunctional SMT pick and place machines is their ability to place components with micron-level accuracy and at speeds that far exceed manual methods. This precision is crucial for the assembly of high-density PCBs and for maintaining the integrity of delicate components.

Cost-Effectiveness:

Automating the assembly process with multifunctional SMT pick and place machines can significantly reduce labor costs and the potential for human error. By investing in these machines, companies can achieve higher throughput and lower production costs, leading to increased profitability.

Versatility in Component Handling:

The versatility of multifunctional SMT pick and place machines is unparalleled. They can handle a wide range of components, from 0201 passives to large BGA and QFN packages. This adaptability allows manufacturers to use a single machine for multiple projects, reducing the need for specialized equipment and simplifying production lines.

Reliability and Consistency:

In the world of electronics, consistency is king. Multifunctional SMT pick and place machines ensure that every component is placed in the exact same position, every time. This consistency is vital for maintaining the quality and reliability of the final product.

Enhancing Production Efficiency:

Automation and Integration:

The automation provided by multifunctional SMT pick and place machines allows for seamless integration with other manufacturing processes. This integration can lead to a fully automated production line, where components are fed, placed, and soldered with minimal human intervention.

Quality Control and Traceability:

Modern multifunctional SMT pick and place machines come equipped with advanced cameras and sensors that can inspect components before placement and verify their position after placement. This built-in quality control ensures that only perfect boards are passed on to the next stage of production.

Scalability and Flexibility:

As production demands change, multifunctional SMT pick and place machines can be easily scaled to meet these needs. Whether you need to increase output or switch to a different product line, these machines offer the flexibility to adapt to changing requirements without the need for significant capital investment.

The Future of Electronics Manufacturing:

Smart Factory Integration:

The future of manufacturing is moving towards smart factories, where data-driven decisions and real-time monitoring are the norm. Multifunctional SMT pick and place machines are at the heart of this transformation, providing the data and connectivity needed to optimize production processes.

Sustainability and Energy Efficiency:

As the world moves towards more sustainable practices, the energy efficiency of manufacturing equipment becomes increasingly important. Multifunctional SMT pick and place machines are designed to consume less energy than traditional assembly methods, reducing the environmental impact of electronics production.

Innovation in Component Placement:

The technology behind multifunctional SMT pick and place machines is constantly evolving. We can expect to see advancements in component recognition, placement speed, and machine learning algorithms that will further enhance the capabilities of these machines.

Conclusion:

The multifunctional SMT pick and place machine is more than just a tool; it's a symbol of progress in the electronics industry. With their precision, versatility, and efficiency, these machines are shaping the future of electronics manufacturing. As we look to the future, the role of multifunctional SMT pick and place machines in our production lines will only grow. They are not just about assembling components; they're about building a smarter, more efficient, and sustainable manufacturing process. Invest in the power of automation, and let the versatility of multifunctional SMT pick and place machines drive your production to new heights.

Final Thoughts:

As we conclude our exploration of multifunctional SMT pick and place machines, it's clear that these machines are not just a part of the manufacturing process; they are the driving force behind it. They represent the intersection of technology, innovation, and efficiency. Embrace the potential of multifunctional SMT pick and place machines, and watch your production capabilities soar to new levels of excellence.