メールフォーマットエラー

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

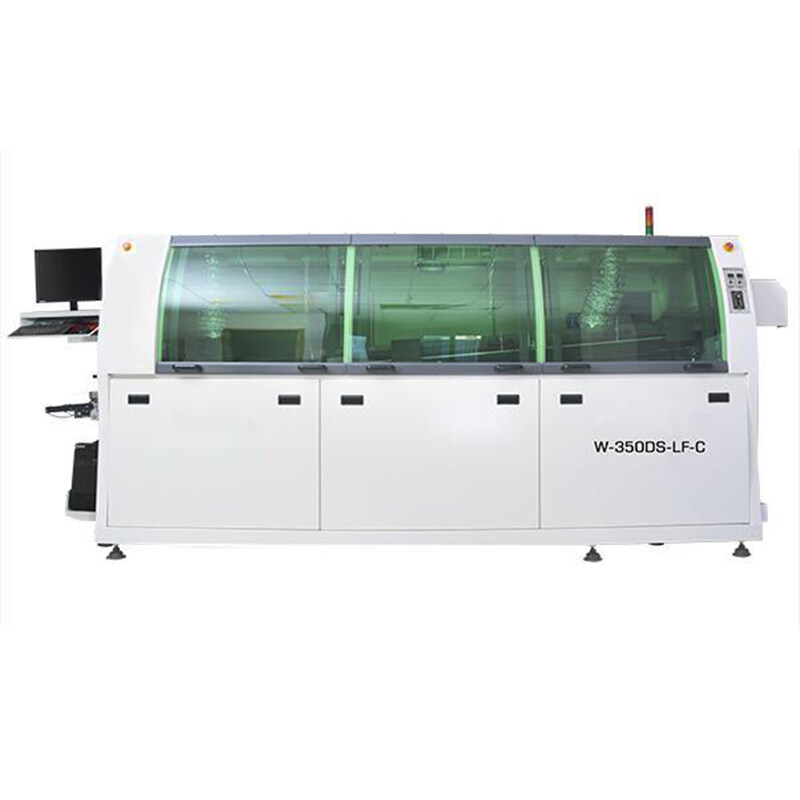

PCB Desk Lead-Free Wave Soldering Machine

In today's rapidly evolving technological landscape, the demand for efficient and environmentally friendly manufacturing processes has never been greater. The PCB desk lead-free wave soldering machine is a game-changing solution designed to address these challenges. There mainly aims to explore the capabilities, benefits, and impact of this advanced machine in the PCB manufacturing industry.

Ⅰ. Understanding PCB Desk Lead-Free Wave Soldering Machine:

1. Unraveling the Technology:

The PCB desk lead-free wave soldering machine embodies cutting-edge technology that allows for the creation of high-quality solder joints on printed circuit boards (PCBs). It employs wave soldering, a technique that uses a wave of molten solder to ensure precise and reliable connections between electronic components and PCBs.

2. Key Components and Functionality:

The machine consists of a preheating zone, fluxing zone, wave soldering zone, and cooling zone. These zones work collaboratively to heat and flux the PCB assemblies, dip them into a solder wave, and finally cool them down, resulting in flawlessly soldered connections.

Ⅱ. The Advantages of PCB Desk Lead-Free Wave Soldering Machine:

1. Lead-Free Soldering: Reducing Environmental Impact:

One of the significant advantages of the PCB desk lead-free wave soldering machine is its ability to use lead-free solder, thereby eliminating the harmful effects of lead on the environment and human health. This aligns with the global objective of reducing hazardous materials in manufacturing processes.

2. Enhanced Efficiency and Quality:

The machine possesses remarkable precision and consistency, resulting in higher quality solder joints. It ensures uniform temperature distribution and reduced thermal stress on components, minimizing the risk of process-related defects. Furthermore, the efficient utilization of heat reduces the chances of overheating or damaging sensitive electronic parts.

3. Increased Production Output:

The advanced features and automation capabilities of the PCB desk lead-free wave soldering machine enable higher production throughput. With reduced cycle times and minimization of human error, manufacturers can achieve increased efficiency and optimize their overall production capacity.

4. Cost Savings:

Implementation of the PCB desk lead-free wave soldering machine can lead to substantial cost savings. Reduced rework and scrap rates, along with enhanced quality control, contribute to minimizing production costs. The elimination of lead solder usage also helps manufacturers adhere to stringent regulations and avoid potential fines.

Ⅲ. Applications and Impact:

1. Wide Range of PCB Assemblies:

The PCB desk lead-free wave soldering machine caters to various industries, including automotive, aerospace, consumer electronics, telecommunications, and healthcare. Its versatility allows soldering of different types of PCB assemblies, regardless of their complexity or size.

2. Streamlined Manufacturing Process:

By automating various soldering stages, the machine enables a seamless and streamlined manufacturing process. This results in faster production cycles, improved turnaround time, and ultimately, reduced time-to-market for products.

3. Meeting Environmental Standards:

With the increasing global focus on sustainability, the use of lead-free solder and the reduction of hazardous materials contribute to a greener manufacturing process. The PCB desk lead-free wave soldering machine plays a significant role in adhering to environmental regulations and ensuring product compliance.

4. Industry Advancement:

The adoption of cutting-edge technologies like the PCB desk lead-free wave soldering machine drives the advancement of the PCB manufacturing industry. It not only improves product quality but also positions manufacturers at the forefront of innovation, allowing them to cater to the ever-growing demands of the market.

PCB Desk Lead Free Wave Soldering Machine with Efficient Productivity

The PCB desk lead-free wave soldering machine represents a major leap forward in PCB manufacturing technology. With its lead-free soldering capabilities, enhanced efficiency, increased productivity, and positive environmental impact, this machine is revolutionizing the industry. Embracing this advanced technology will undoubtedly result in improved product quality, reduced costs, and a more sustainable future for the PCB manufacturing sector.