メールフォーマットエラー

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

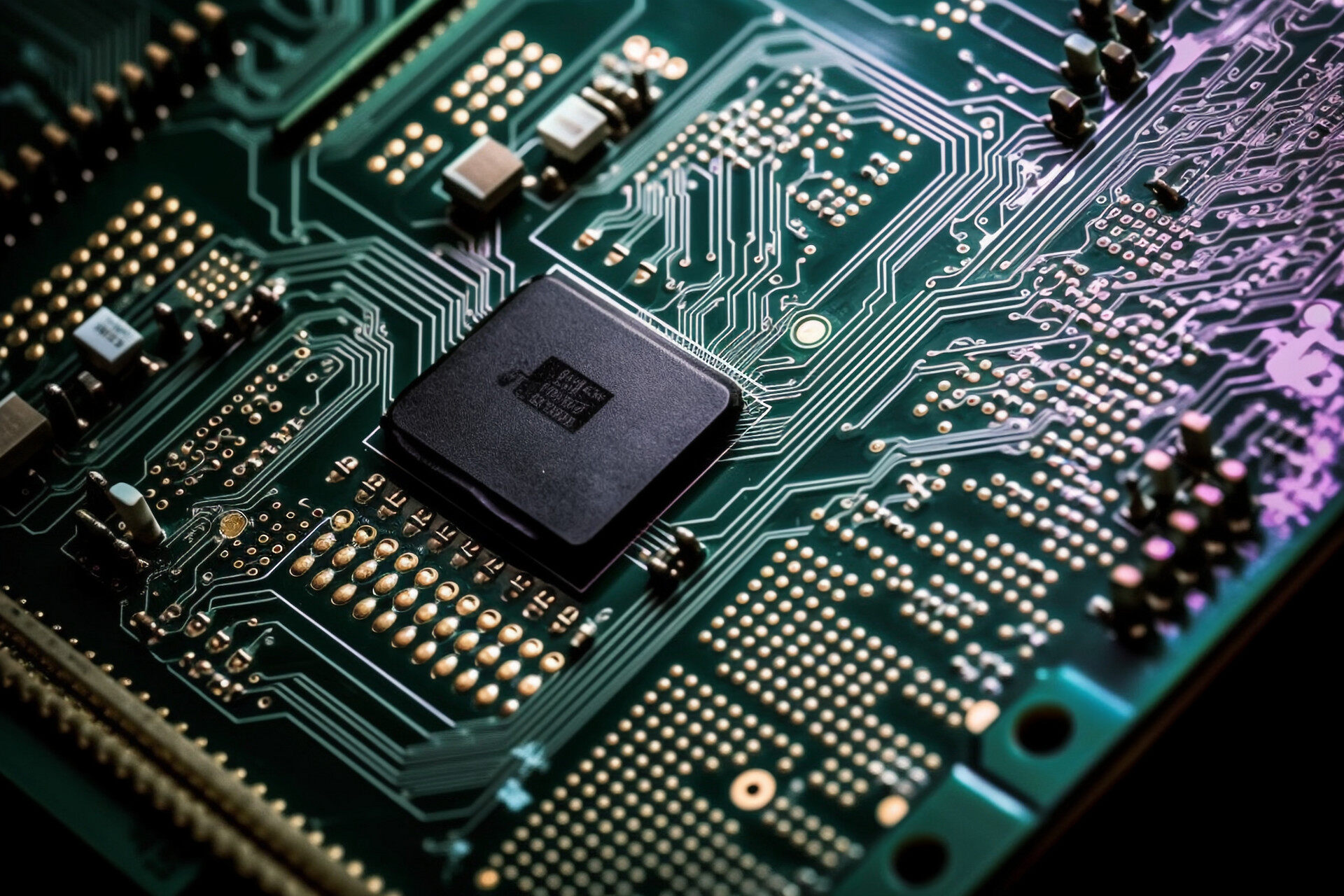

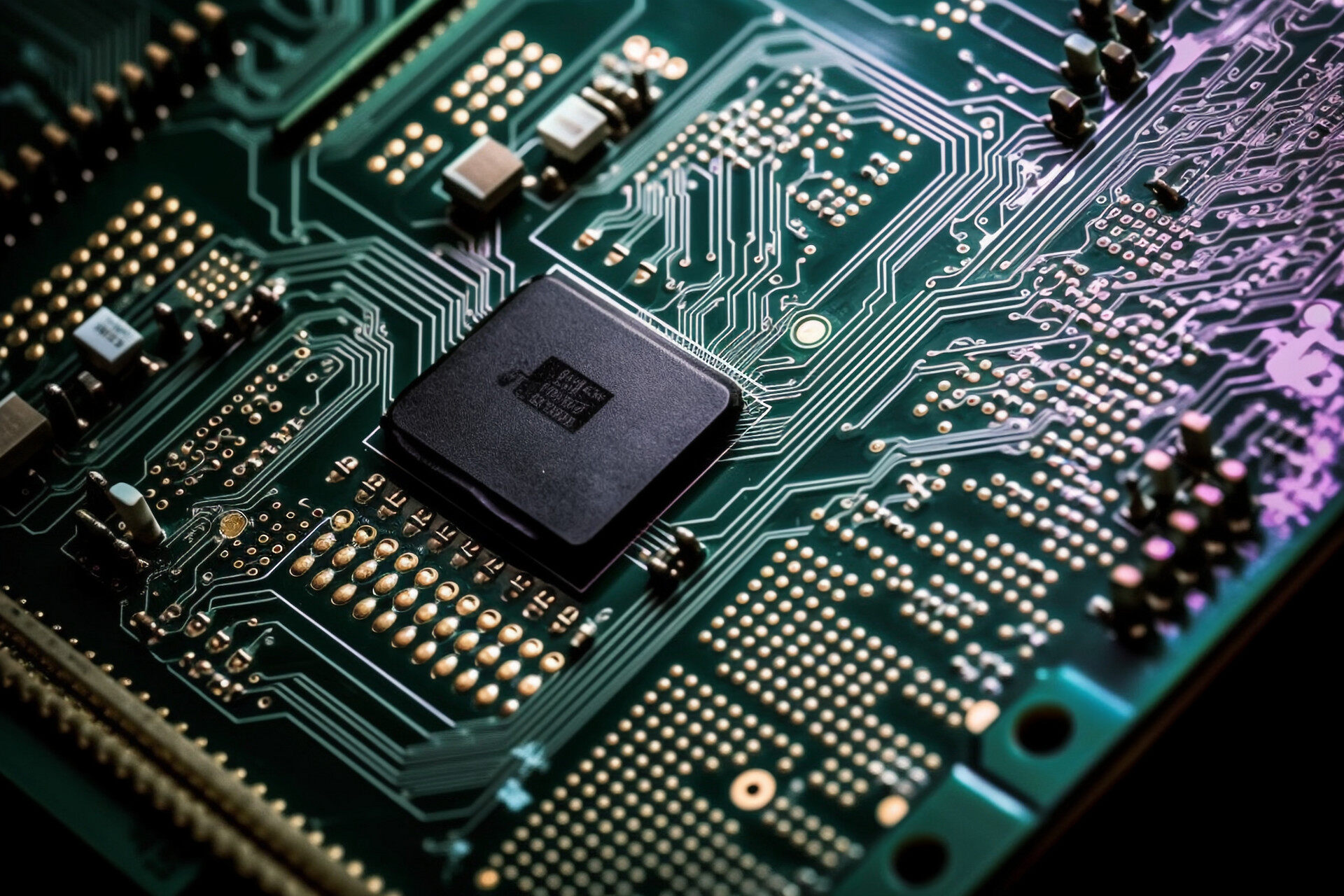

Precision Crafting: The Evolution of SMT PCB Assembly

Introduction

In the intricate realm of electronics manufacturing, the landscape has been continually shaped by innovations that cater to the demand for smaller, more efficient devices. This shift towards miniaturisation has propelled the significance of Surface Mount Technology (SMT) PCB assembly, a process that intricately interweaves precision and efficiency in crafting the electronic marvels of our age.

Understanding SMT PCB Assembly: Pioneering Miniaturisation

In the era of consumer electronics, where gadgets seem to shrink with each passing day, the advent of SMT PCB assembly stands as a pivotal chapter. Unlike traditional through-hole assembly methods, SMT embraces a paradigm shift in design, ensuring that every component plays a role in the relentless pursuit of miniaturisation. The integration of Surface Mount Devices (SMDs) becomes a cornerstone in this journey, revolutionising the very essence of electronic circuitry.

As technology advances, the push for miniaturisation transcends mere aesthetics. Engineers and designers harness the power of SMT to maximise the functionality of devices, emphasising the importance of SMDs and intricate PCB substrates in achieving this delicate balance.

Solder Paste Stencil Printing: Precision Redefined

In the meticulous dance of SMT PCB assembly, solder paste stencil printing emerges as a choreographer of precision. The stencil, a seemingly humble component, plays a crucial role in the application of solder paste, ensuring that each connection is executed with the utmost accuracy. The importance of proper aperture design cannot be overstated; it is the silent conductor orchestrating the symphony of connectivity on the circuit board.

Within the realm of SMT, solder paste stencil printing operates at the intersection of art and science. Engineers craft stencils with advanced materials and innovative techniques, pushing the boundaries of what was once deemed possible in the realm of precision electronics assembly.

Circuit Board Printing Machines: Crafting Tomorrow's Devices

As SMT PCB assembly evolves, so too do the machines that bring these intricate designs to life. Cutting-edge circuit board printing machines, ranging from pick-and-place to reflow, are the unsung heroes behind the scenes. Leading manufacturers compete to provide the latest models, each equipped with features that enhance the efficiency and accuracy of the assembly process.

From the perspective of manufacturing, the selection of a suitable PCB printing machine is a decision that reverberates across the entire production line. Engineers weigh the capabilities of these machines, considering factors such as speed, accuracy, and adaptability to emerging technologies.

Advancements in SMT PCB Assembly Technologies: Bridging the Future

The journey of SMT PCB assembly is a perpetual exploration of possibilities. Recent trends indicate a fusion of traditional craftsmanship with the cutting-edge of Industry 4.0. As technology converges with intelligent manufacturing, SMT assembly plants are becoming hubs of innovation, incorporating artificial intelligence and data analytics to streamline processes and enhance quality control.

The synergy between traditional craftsmanship and modern technology showcases the versatility of SMT PCB assembly. As we navigate towards a future where smart factories become the norm, the role of SMT assembly will continue to be pivotal in shaping the electronics landscape.

Conclusion: SMT PCB Assembly: A Symphony of Precision and Progress

In the grand symphony of electronics manufacturing, SMT PCB assembly plays a pivotal role, harmonising precision, efficiency, and innovation. From the vantage point of engineers, designers, and manufacturers, this intricate dance of components and machines crafts the devices that define our connected world. As we stand at the cusp of a new technological era, SMT PCB assembly remains an enduring force, propelling us towards a future where the devices we create mirror the precision and progress inherent in the artistry of SMT assembly.