メールフォーマットエラー

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

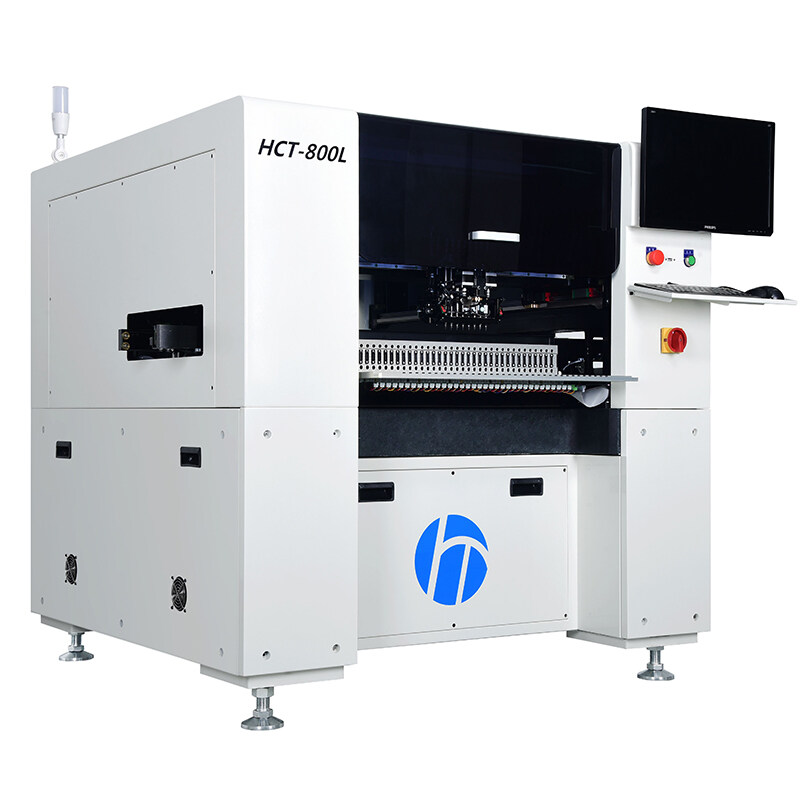

Revolutionizing Electronics Manufacturing with Mini SMT Pick and Place Machines

In the dynamic landscape of electronics manufacturing, efficiency and precision are paramount. With the advent of mini SMT (Surface Mount Technology) pick and place machines, a new era has dawned upon the industry. These compact yet powerful machines are reshaping the way electronic components are assembled onto printed circuit boards (PCBs). In this comprehensive guide, we delve into the intricacies of mini SMT pick and place machines, exploring their benefits, applications, and the future they herald.

Understanding Mini SMT Pick and Place Machines

Mini SMT pick and place machines are compact automated assembly systems designed to precisely place electronic components onto PCBs. They offer a scaled-down alternative to traditional pick and place machines, catering to the needs of small to medium-sized manufacturers, prototyping labs, and hobbyists. Despite their smaller footprint, these machines boast impressive capabilities, leveraging advanced technologies for high-speed and high-accuracy component placement.

Benefits of Mini SMT Pick and Place Machines

1. Cost-Effectiveness: The pick and place machines offer a cost-effective solution for electronics manufacturing, minimizing the initial investment required for automated assembly. By streamlining the assembly process and reducing labor costs, these machines provide a rapid return on investment for businesses of all sizes.

2. Space Efficiency: Their compact size makes them ideal for environments where space is limited, such as small-scale production facilities or research laboratories. Unlike their larger counterparts, the pick and place machines can be easily integrated into existing workspaces without the need for extensive reconfiguration.

3. Ease of Use: With user-friendly interfaces and intuitive software, these machines are accessible to both seasoned professionals and enthusiasts alike. Manufacturers can quickly program the machines to accommodate different PCB designs, while hobbyists can enjoy the convenience of plug-and-play operation for their projects.

4. Versatility: Despite their diminutive stature, these machines are capable of handling a wide range of component sizes and types, from tiny resistors to larger integrated circuits. This versatility allows manufacturers to produce a diverse array of electronic devices without the need for multiple assembly systems.

Applications of Mini SMT Pick and Place Machines

1. Prototyping: These pick and place machines are invaluable tools for rapid prototyping, allowing designers to quickly assemble and test PCB designs before full-scale production. By reducing time-to-market and enabling iterative design improvements, these machines facilitate innovation in product development.

2. Small Batch Production: They are well-suited for small batch production runs, enabling manufacturers to efficiently produce limited quantities of electronic devices without the need for large-scale machinery. This flexibility is particularly beneficial for niche markets or custom applications where demand fluctuates unpredictably.

3. Custom Electronics: Hobbyists and DIY enthusiasts can leverage machines to create custom electronic projects, from Arduino-based gadgets to IoT (Internet of Things) devices. By eliminating the need for manual soldering and assembly, these machines empower hobbyists to focus on creativity and experimentation.

4. Educational Purposes: These machines serve as educational aids in universities and technical institutes, providing students with hands-on experience in electronic assembly and manufacturing processes. By exposing students to industry-standard equipment and techniques, educators prepare them for careers in fields such as engineering, robotics, and mechatronics.

Key Features to Consider

1. Placement Accuracy: Look for machines with high placement accuracy, typically measured in microns, to ensure precise component placement. This level of precision is essential for achieving reliable electrical connections and optimizing PCB performance.

2. Component Compatibility: Ensure compatibility with a wide range of electronic components, including various package types and sizes. From surface-mount resistors to ball grid array (BGA) chips, the machine should support the full spectrum of components used in modern electronics.

3. Software Integration: Choose machines that integrate seamlessly with industry-standard CAD (Computer-Aided Design) software for streamlined PCB design and assembly. This integration simplifies the transition from design to manufacturing, reducing the risk of errors and inconsistencies.

4. Feeder Capacity: Consider the number and type of component feeders supported by the machine, as this can impact production efficiency. Machines with multiple feeder slots and quick-change mechanisms allow for rapid setup and reconfiguration, minimizing downtime during production runs.

Future Outlook

The future of mini SMT pick and place machines is brimming with possibilities. As technology continues to advance, we can expect these machines to become even more compact, efficient, and intelligent. Innovations such as machine learning and computer vision hold the potential to further enhance their capabilities, enabling autonomous operation and adaptive assembly processes. Moreover, with the growing demand for smaller and more interconnected electronic devices, mini SMT pick and place machines are poised to play a pivotal role in shaping the future of electronics manufacturing.

Conclusion

In conclusion, mini SMT pick and place machines represent a paradigm shift in electronics manufacturing, offering unparalleled efficiency, precision, and versatility in a compact package. Whether you're a professional manufacturer, a hobbyist, or an educator, these machines open up a world of possibilities for innovation and creativity. By harnessing the power of mini SMT pick and place technology, we can pave the way for a smarter, more connected future in electronics manufacturing.