メールフォーマットエラー

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

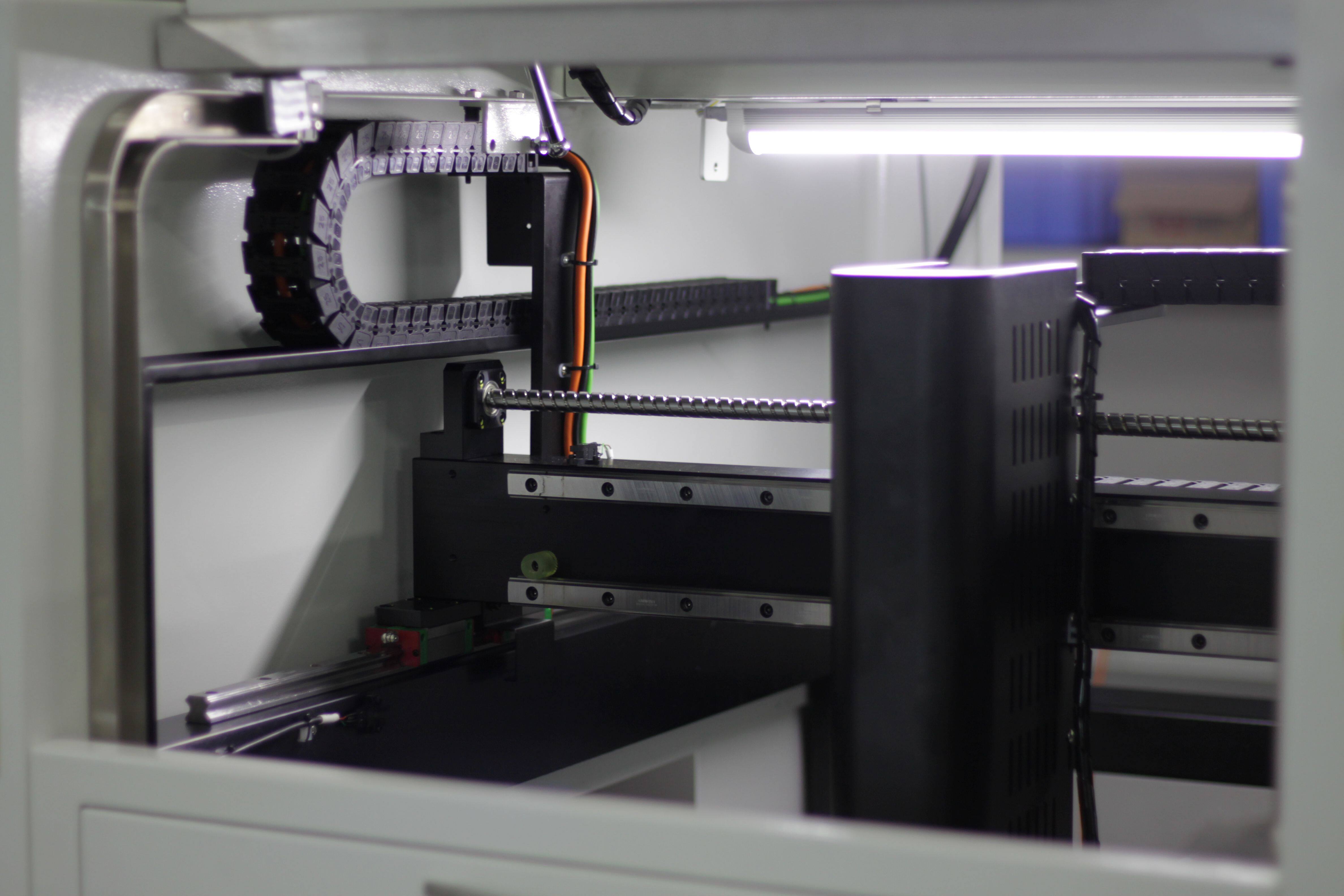

Smt Solder Paste Screen Printer Machine

The SMT (Surface Mount Technology) solder paste screen printer machine is a pivotal component in electronic manufacturing, facilitating the accurate deposition of solder paste onto printed circuit boards (PCBs) during surface mount assembly processes. It plays a critical role in ensuring precise solder paste application, which is essential for creating reliable electrical connections between surface mount components and the PCB. Below is an overview of the key features and operation of the SMT solder paste screen printer machine:

Key Features:

-

High Precision Printing: The machine utilizes advanced printing mechanisms to achieve high precision and accuracy in solder paste deposition onto PCBs.

-

Automatic Control: Equipped with automated controls and programmable settings for precise adjustment of printing parameters, such as solder paste volume, speed, and pressure.

-

Vision Alignment System: Some models feature a vision alignment system that accurately aligns the stencil with the PCB, ensuring precise solder paste deposition on designated areas.

-

Adjustable Stencil Frame: The machine accommodates various sizes of stencil frames, allowing flexibility in stencil selection based on PCB dimensions and design requirements.

-

Quick Changeover: Designed for quick and efficient changeover between different PCB designs, minimizing downtime and increasing production efficiency.

-

User-Friendly Interface: Features an intuitive user interface with easy-to-use controls for convenient operation and setup by operators.

-

Cleaning and Maintenance: Incorporates features for easy cleaning and maintenance to ensure optimal performance and longevity of the machine.

Operation:

-

Stencil Preparation: A stainless steel stencil with openings corresponding to solder paste deposition areas on the PCB is prepared. The stencil is securely mounted onto the stencil frame of the printer machine.

-

PCB Alignment: The PCB is securely fixed onto the machine's worktable, ensuring proper alignment with fiducial marks or alignment pins.

-

Solder Paste Application: Solder paste is dispensed onto the stencil surface, covering the openings corresponding to soldering areas on the PCB.

-

Printing Process: The machine's printing mechanism, typically a squeegee or blade, spreads the solder paste evenly across the stencil surface, forcing it through the openings and depositing it onto the PCB in precise locations.

-

Vision Alignment (Optional): If equipped with a vision alignment system, the machine automatically aligns the stencil with the PCB based on fiducial marks or reference points for accurate solder paste deposition.

-

Post-Printing Inspection: Automated inspection systems may be used to verify the quality of solder paste deposition, ensuring proper volume, alignment, and absence of defects.

-

Cleaning and Maintenance: After printing, the stencil and machine are cleaned to remove excess solder paste and prevent contamination. Periodic maintenance is performed to ensure optimal performance.

The Surface Mount Technology (SMT) solder paste screen printer machine is a critical component in the surface mount assembly process for printed circuit boards (PCBs). It is responsible for accurately depositing solder paste onto the pads of the PCB using a stencil to define the solder paste pattern.

-

Machine Setup:

- The SMT solder paste screen printer machine is set up with a stencil, which is typically made of stainless steel and contains openings (apertures) that correspond to the pads on the PCB where solder paste will be deposited.

- The stencil is securely mounted onto the printer's frame, and the printer's settings are configured based on the PCB layout and solder paste requirements.

-

PCB Alignment:

- The PCB is placed onto the printer's bed or platform, and alignment pins or fiducial marks on the PCB and stencil ensure precise alignment between the two during the printing process.

- Automated vision systems may be used to verify alignment and compensate for any slight variations in PCB positioning.

-

Solder Paste Application:

- Solder paste, a mixture of solder alloy particles and flux, is loaded into the printer's solder paste dispensing system.

- The solder paste is then deposited onto the stencil using a squeegee or blade, which passes over the stencil, forcing the solder paste through the apertures and onto the PCB pads in a controlled manner.

- The printer's settings, including squeegee pressure, speed, and angle, are carefully adjusted to achieve uniform solder paste deposition across the PCB.

-

Inspection and Verification:

- After solder paste printing, the PCB may undergo inspection to ensure the quality and accuracy of the solder paste deposition.

- Automated optical inspection (AOI) systems or manual visual inspection may be performed to detect defects such as insufficient or excessive solder paste, bridging between pads, or misalignment.

-

Reflow Soldering:

- Once the solder paste is applied to the PCB, the assembly moves to the reflow soldering stage.

- During reflow soldering, the PCB is heated in a controlled atmosphere to melt the solder paste and form solder joints between the components and PCB pads.

- The reflow process solidifies the solder joints, creating reliable electrical connections between the components and the PCB.

-

Post-Printing Cleaning (Optional):

- In some cases, especially for critical applications or assemblies with fine-pitch components, post-printing cleaning may be performed to remove excess solder paste residue from the PCB surface.

- Cleaning processes may include solvent cleaning, aqueous cleaning, or vapor phase cleaning, depending on the requirements of the application and environmental considerations.

-

Quality Assurance:

- Throughout the entire SMT solder paste printing process, quality assurance measures are implemented to ensure the integrity and reliability of the solder joints.

- Process control, inspection, and monitoring techniques are used to identify and rectify any issues that may affect the quality of the final product.

By following these steps and utilizing advanced SMT solder paste screen printer machines, manufacturers can achieve consistent and reliable solder paste deposition, contributing to the overall quality and performance of electronic assemblies produced through the SMT process.