メールフォーマットエラー

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

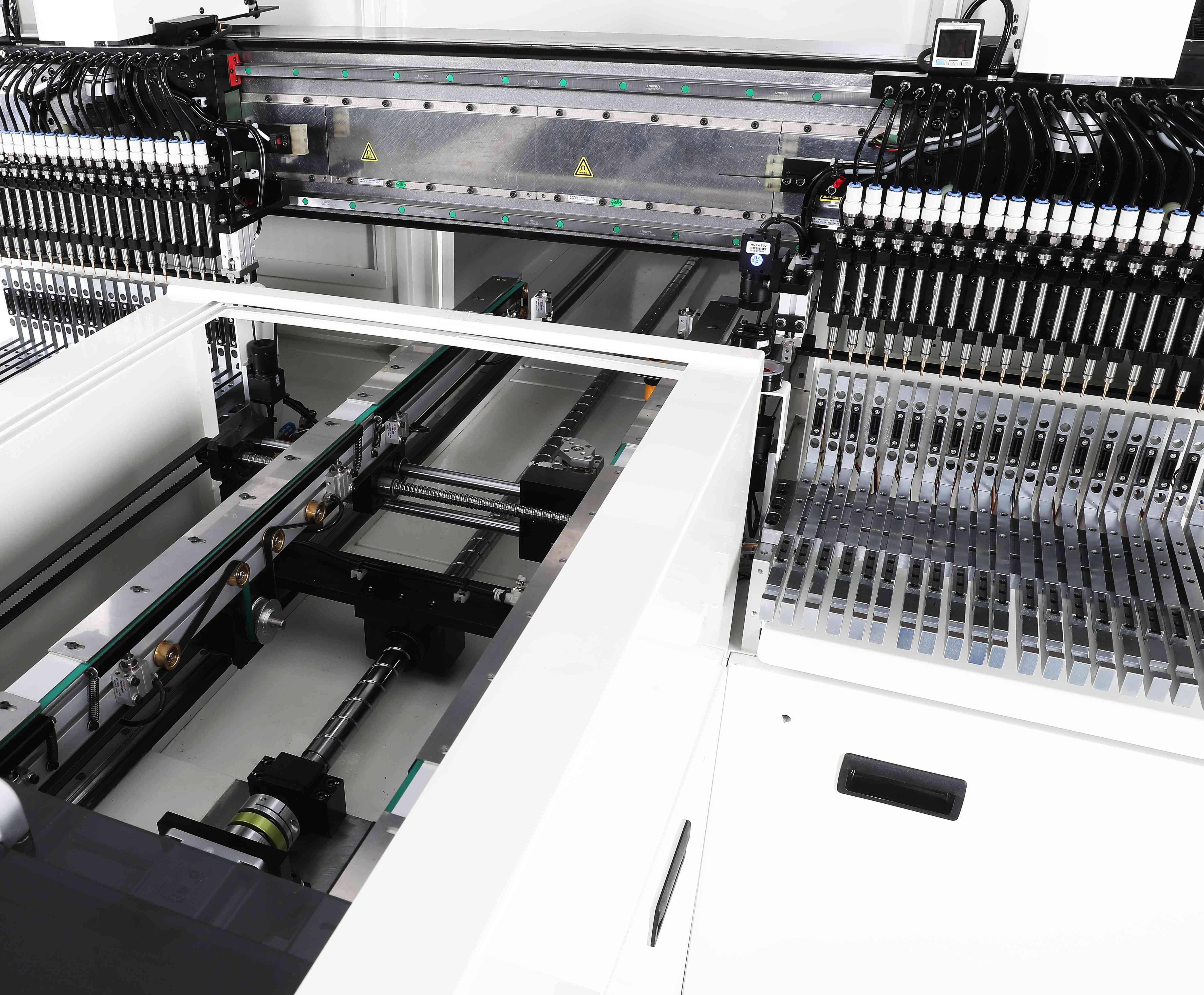

The Impact of LED Chip Mounters on the Quality of LED Lighting Products

LED (Light Emitting Diode) technology has revolutionized the lighting industry, offering energy-efficient and long-lasting lighting solutions. Behind every high-quality LED lighting product lies an essential component—the LED chip mounter. LED chip mounters play a crucial role in the production process, ensuring precise and reliable placement of LED chips onto circuit boards. In this blog, we will explore the significant impact of LED chip mounters on the quality of LED lighting products and the benefits they bring to manufacturers and consumers alike.

1. Achieving Precision Placement

LED chip mounters utilize advanced robotic technology to achieve precise placement of LED chips on circuit boards. These machines can accurately position and solder hundreds or even thousands of LED chips per minute, ensuring consistent quality and uniformity in the final product. The precise placement of LED chips leads to improved performance, minimized defects, and enhanced reliability of LED lighting products.

2. Enhancing Efficiency and Productivity

LED chip mounters significantly improve production efficiency and productivity in the manufacturing process. With their high-speed placement capabilities, these machines can handle large volumes of LED chips, reducing manual labor and assembly time. By automating the mounting process, manufacturers can achieve faster production cycles, meet demanding deadlines, and increase overall output. This efficiency not only benefits manufacturers but also allows for faster availability of LED lighting products in the market.

3. Ensuring Consistency and Reliability

Consistency and reliability are crucial factors for LED lighting products. LED chip mounters provide consistent placement and soldering of LED chips, ensuring uniformity across the entire production batch. By eliminating human error and variability, these machines deliver reliable results, reducing the chances of defects and failures in LED lighting products. Consistent performance and reliability contribute to the reputation of manufacturers and instill confidence in consumers.

4. Improving Product Quality and Longevity

LED chip mounters play a vital role in improving the quality and longevity of LED lighting products. Precise placement and secure soldering of LED chips lead to better thermal management, reducing the risk of overheating and premature failure. Additionally, the accurate positioning of chips minimizes the strain on other components, optimizing the overall performance and lifespan of LED lighting products. By ensuring high-quality assembly, LED chip mounters contribute to the longevity and durability of LED lighting products.

5. Supporting Customization and Innovation

LED chip mounters enable manufacturers to explore new design possibilities and support customization in LED lighting products. With their flexibility in accommodating various LED chip sizes and configurations, these machines empower manufacturers to create unique lighting solutions tailored to specific applications and customer requirements. LED chip mounters provide the foundation for innovation, allowing manufacturers to stay competitive in a dynamic market.

Conclusion

LED chip mounters are indispensable in the production of high-quality LED lighting products. Through precise placement, enhanced efficiency, and consistent performance, these machines contribute to the overall quality, reliability, and longevity of LED lighting products. Manufacturers benefit from improved productivity, customization options, and a strengthened reputation, while consumers enjoy reliable, energy-efficient, and long-lasting lighting solutions. As the demand for LED lighting continues to rise, the role of LED chip mounters becomes increasingly vital in shaping the future of the industry.