メールフォーマットエラー

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Wholesale LED SMT Production Line: Revolutionizing the LED Manufacturing Industry

In recent years, the demand for LEDs (Light Emitting Diodes) has surged dramatically, driven by their energy efficiency, long lifespan, and versatility across various applications. As a result, the need for a sophisticated and efficient production process has never been higher. This is where the wholesale LED SMT production line comes into play. In this blog, we will delve into the intricacies of an LED SMT (Surface Mount Technology) production line, its advantages, and its impact on the LED manufacturing industry.

Understanding the LED SMT Production Line

What is an SMT Production Line?

Surface Mount Technology (SMT) is a method used for producing electronic circuits in which the components are mounted or placed directly onto the surface of printed circuit boards (PCBs). An SMT production line typically consists of several key stages: solder paste printing, component placement, reflow soldering, and inspection. When tailored for LED production, these lines are optimized to handle the specific requirements of LED components, which differ in size, shape, and functionality compared to other electronic components.

Key Components of a Wholesale LED SMT Production Line

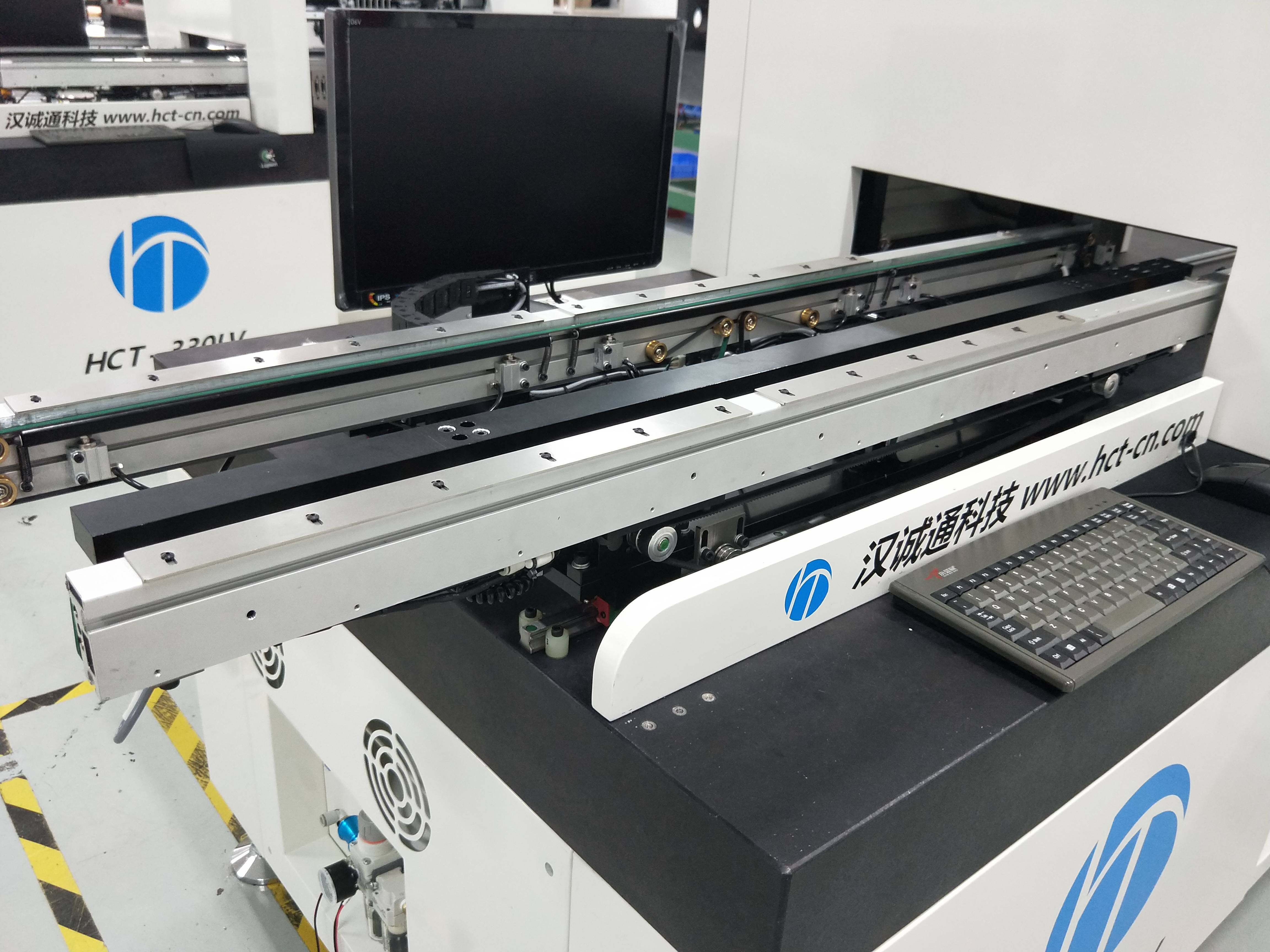

Solder Paste Printer: This machine applies solder paste to the PCB where the components will be placed. Precision is critical to ensure that the solder joints are strong and reliable.

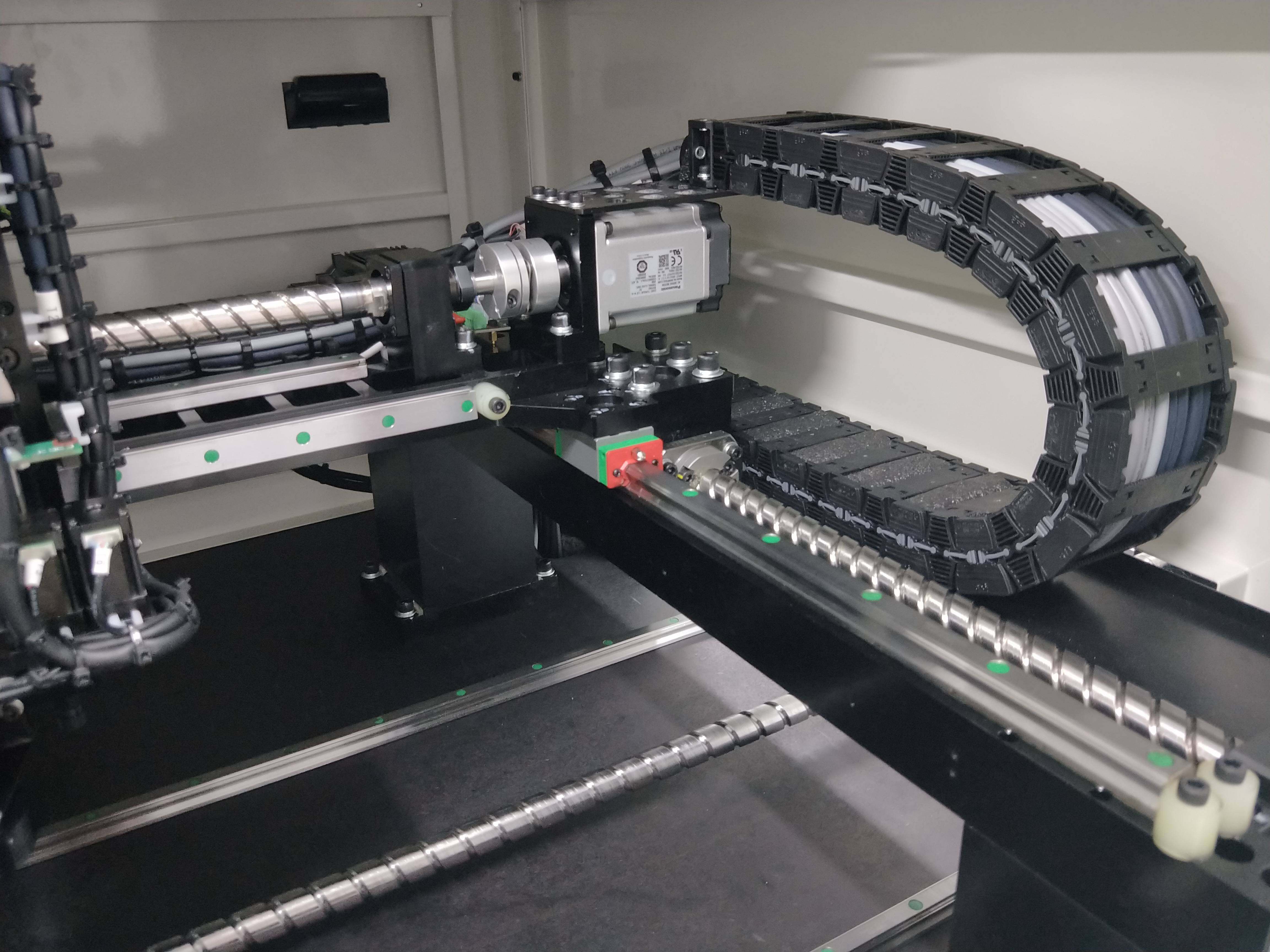

Pick and Place Machine: This machine accurately places LED components onto the PCB. Speed and accuracy are crucial, especially in a wholesale production environment where large volumes are produced.

Reflow Oven: After the components are placed, the PCB passes through a reflow oven where the solder paste is melted to create a strong bond between the components and the PCB.

Automated Optical Inspection (AOI) Machine: This machine inspects the PCB for any defects such as missing components, misalignment, or soldering issues. Ensuring high quality in wholesale production is essential to maintain customer satisfaction and reduce returns.

Advantages of Using a Wholesale LED SMT Production Line

Efficiency and Speed: A well-optimized SMT production line can handle large volumes of LEDs with high precision and speed, crucial for meeting wholesale demands.

Consistency and Quality: Automation in SMT production lines ensures consistent quality across all produced units, reducing the risk of defects and enhancing reliability.

Cost-Effectiveness: By streamlining the production process and minimizing manual intervention, a wholesale LED SMT production line can significantly reduce labor costs and material waste.

Setting Up a Wholesale LED SMT Production Line

Initial Planning and Design

Setting up a wholesale LED SMT production line requires careful planning and design. The first step is to assess the production requirements, including the type of LEDs to be manufactured, production volumes, and quality standards. This information will guide the selection of equipment and the layout of the production line.

Selecting the Right Equipment

Investing in high-quality equipment is crucial for the success of an SMT production line. Each component, from the solder paste printer to the AOI machine, should be selected based on its performance, reliability, and compatibility with other machines in the line. For wholesale production, scalability and ease of maintenance are also important considerations.

Layout and Workflow Optimization

The layout of the production line should be designed to minimize material handling and maximize efficiency. A well-organized workflow ensures that each stage of the production process flows smoothly into the next, reducing bottlenecks and downtime. Additionally, implementing lean manufacturing principles can help identify and eliminate waste, further enhancing productivity.

The Role of Automation in LED SMT Production

Enhancing Precision and Accuracy

Automation plays a vital role in the SMT production process, particularly in the placement of components and the reflow soldering stages. Automated pick and place machines can position components with remarkable precision, ensuring that each LED is correctly aligned and soldered. This level of accuracy is difficult to achieve with manual processes, especially in high-volume production.

Improving Inspection and Quality Control

Automated Optical Inspection (AOI) machines are essential for maintaining high quality in wholesale LED production. These machines use advanced imaging technology to detect defects that might be missed by human inspectors. By identifying issues early in the production process, AOI machines help prevent defective products from reaching the market, protecting the manufacturer's reputation and reducing costly returns.

Reducing Labor Costs

By automating key stages of the production process, manufacturers can significantly reduce labor costs. While skilled technicians are still needed to operate and maintain the equipment, the overall labor requirement is much lower compared to manual assembly processes. This reduction in labor costs can be a major competitive advantage in the wholesale market, where price competition is fierce.

Challenges and Solutions in Wholesale LED SMT Production

Managing Production Volume and Flexibility

One of the main challenges in wholesale LED production is managing large production volumes while maintaining flexibility to accommodate different types of LEDs. To address this, manufacturers can invest in modular production lines that can be quickly reconfigured for different products. Additionally, implementing advanced production planning and scheduling software can help optimize production runs and minimize changeover times.

Ensuring Component Quality

The quality of the final product is heavily dependent on the quality of the components used. Sourcing high-quality LEDs and other components is crucial for maintaining the reliability and performance of the finished products. Establishing strong relationships with reputable suppliers and implementing stringent incoming inspection procedures can help ensure consistent component quality.

Keeping Up with Technological Advancements

The LED industry is constantly evolving, with new technologies and manufacturing techniques emerging regularly. Staying up-to-date with these advancements is essential for maintaining a competitive edge. Manufacturers should invest in ongoing training for their staff and be willing to upgrade their equipment and processes as needed to keep pace with industry developments.

Case Study: Successful Implementation of a Wholesale LED SMT Production Line

Company Overview

XYZ Lighting Solutions, a leading provider of LED lighting products, recently upgraded their production facilities with a state-of-the-art wholesale LED SMT production line. The company sought to increase production capacity, improve product quality, and reduce costs to better compete in the global market.

Implementation Process

The implementation process began with a thorough assessment of the company's production needs and goals. Based on this assessment, XYZ Lighting Solutions selected a combination of high-performance equipment, including a precision solder paste printer, a high-speed pick and place machine, a reflow oven with advanced temperature control, and an AOI machine with 3D inspection capabilities.

The new production line was designed with a modular layout, allowing for quick reconfiguration to accommodate different LED products. Lean manufacturing principles were applied to optimize workflow and reduce waste, and staff were trained on the new equipment and processes.

Results and Benefits

Since implementing the new wholesale LED SMT production line, XYZ Lighting Solutions has seen significant improvements in production efficiency and product quality. The company's production capacity has increased by 50%, while defect rates have decreased by 30%. Additionally, the reduction in labor costs and material waste has resulted in substantial cost savings.

Future Trends in LED SMT Production

Advanced Automation and Robotics

The future of LED SMT production lies in further advancements in automation and robotics. Emerging technologies such as collaborative robots (cobots) and AI-driven production management systems are set to revolutionize the manufacturing process. These innovations promise to enhance precision, reduce downtime, and increase overall efficiency.

Integration of IoT and Smart Manufacturing

The integration of the Internet of Things (IoT) and smart manufacturing technologies is another key trend in the LED industry. IoT-enabled equipment can provide real-time data on production performance, allowing manufacturers to monitor and optimize their processes continuously. Smart manufacturing systems can also predict maintenance needs and detect potential issues before they cause downtime, further enhancing productivity and reliability.

Sustainable Manufacturing Practices

As environmental concerns become increasingly important, sustainable manufacturing practices are gaining traction in the LED industry. Companies are seeking ways to reduce their carbon footprint, minimize waste, and use eco-friendly materials in their production processes. Implementing energy-efficient equipment and recycling programs are just a few ways that manufacturers can contribute to a more sustainable future.

Conclusion

The wholesale LED SMT production line is a game-changer for the LED manufacturing industry. By combining advanced automation with meticulous quality control, these production lines enable manufacturers to produce high volumes of LEDs with exceptional efficiency and consistency. While challenges remain, ongoing advancements in technology and manufacturing practices offer exciting opportunities for continued improvement and innovation.

Investing in a wholesale LED SMT production line is not just about meeting current demand; it's about preparing for the future of the LED industry. As the market continues to grow and evolve, manufacturers who embrace these technologies and practices will be well-positioned to lead the way, delivering high-quality, cost-effective LED products to customers around the world.