メールフォーマットエラー

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

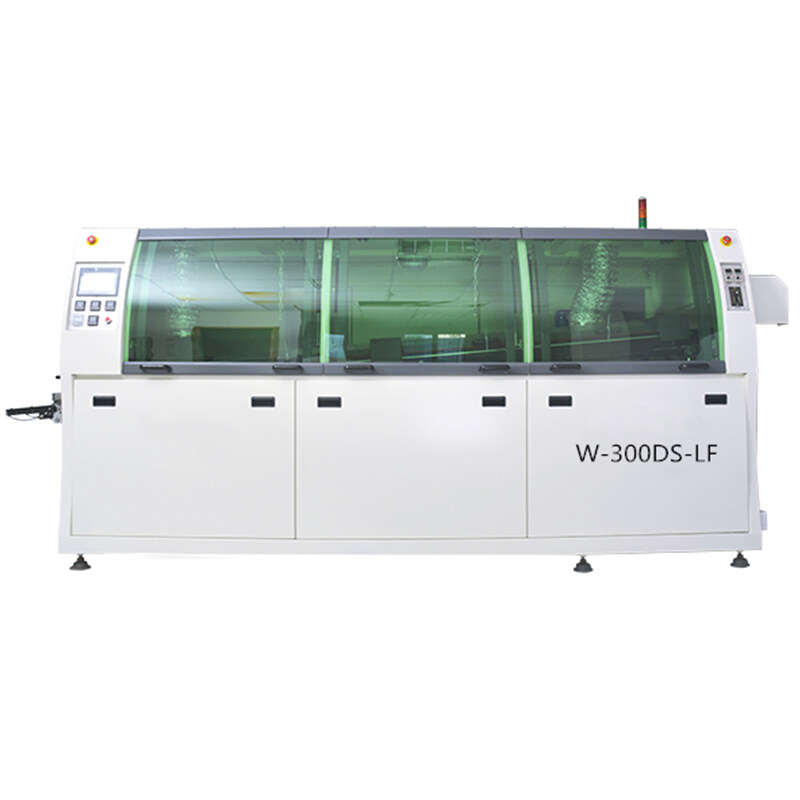

Innovations in Lead-Free Wave Solder Machines: Pioneering a Sustainable Future

The quest for sustainability and environmental responsibility has become paramount in the realm of electronics manufacturing. One significant stride in this direction is the adoption of lead-free wave solder machines. These cutting-edge devices not only ensure compliance with regulatory standards but also pave the path towards a greener, more sustainable future.

Understanding Lead-Free Wave Solder Machines

Lead-free wave solder machines represent a paradigm shift in electronic manufacturing. Unlike their traditional counterparts, these advanced systems eliminate the use of lead, a toxic metal known for its adverse environmental and health impacts. By harnessing innovative technologies, the solder machines offer a safe and efficient alternative for soldering electronic components onto PCBs.

Advantages of Lead-Free Wave Solder Machines

1. Environmental Sustainability: The solder machines significantly reduce the ecological footprint of electronic manufacturing processes. By eliminating lead, these machines mitigate the risk of soil and water contamination, safeguarding ecosystems for future generations.In traditional wave soldering processes, the use of lead-based solder poses a significant environmental threat. Lead, when released into the environment through improper disposal or recycling practices, can accumulate in soil and water, posing risks to wildlife and human health. The solder machines address this concern by utilizing lead-free solder alloys, thereby minimizing the environmental impact of soldering operations.

2. Health Benefits: The absence of lead in soldering processes translates to improved occupational health and safety standards for workers in electronics manufacturing facilities. Lead exposure, a significant concern in conventional soldering operations, is effectively minimized with the adoption of the solder machines.Workers in electronics manufacturing facilities are often exposed to lead fumes and dust during soldering processes, posing serious health risks such as lead poisoning and respiratory ailments. The solder machines mitigate these risks by eliminating the use of lead, thus creating safer working environments for employees.

3. Regulatory Compliance: In an era of stringent environmental regulations, the solder machines offer manufacturers a means to ensure compliance with legal requirements. By adhering to international standards such as RoHS (Restriction of Hazardous Substances), companies can bolster their reputation as responsible corporate citizens.RoHS directives restrict the use of hazardous substances, including lead, in electrical and electronic equipment. The solder machines enable manufacturers to meet these regulatory requirements, thereby avoiding penalties and market access restrictions associated with non-compliance.

Technological Innovations Driving Lead-Free Wave Solder Machines

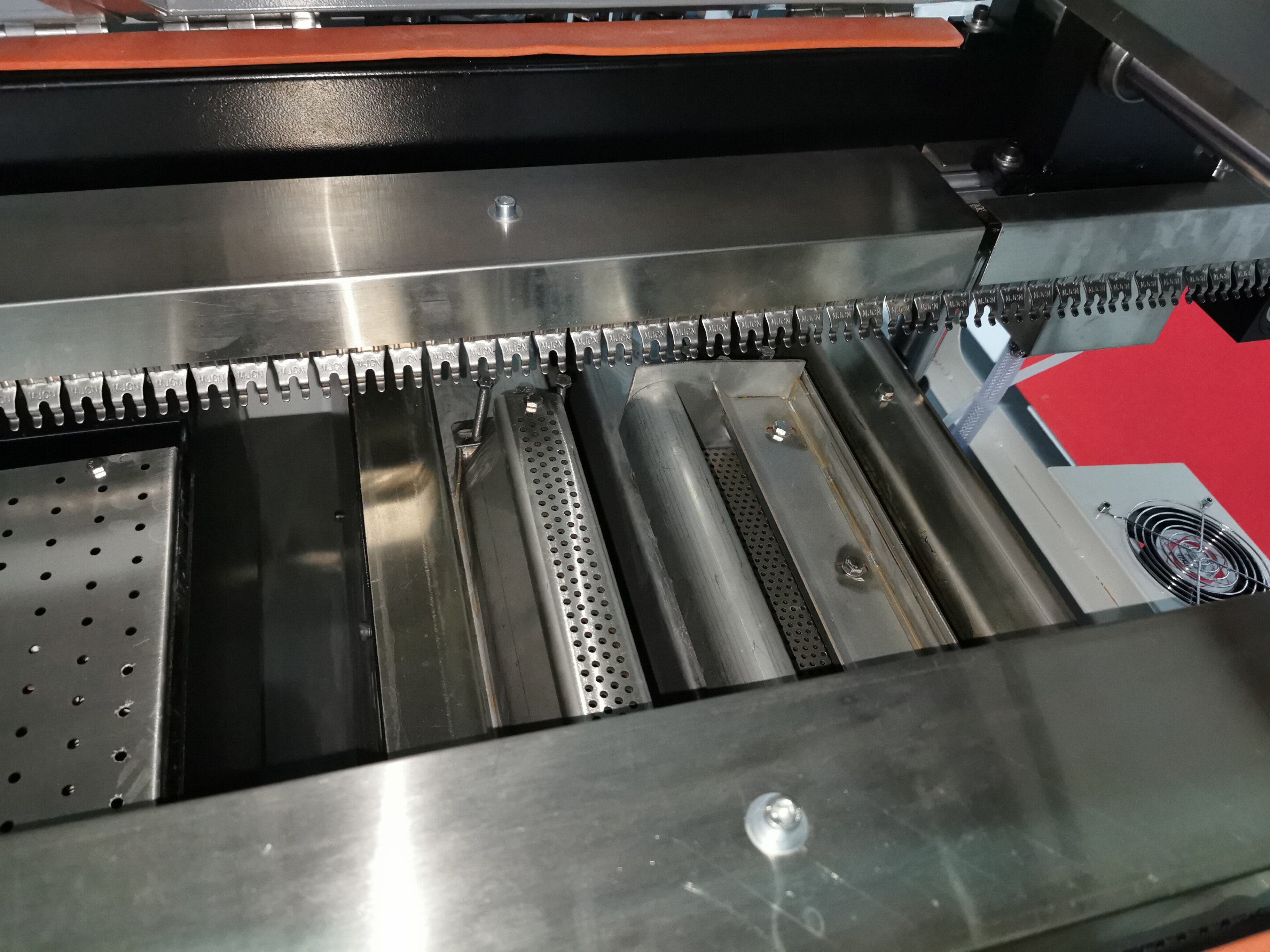

1. Selective Soldering Capabilities: Modern solder machines are equipped with advanced selective soldering features, allowing for precise and targeted solder application. This ensures optimal solder joint quality while minimizing material waste.Selective soldering technology enables manufacturers to solder specific areas of a PCB with high precision, reducing the consumption of solder and minimizing the risk of solder bridging or other defects. By selectively applying solder only to designated areas, lead-free wave solder machines optimize solder usage and improve overall process efficiency.

2. Inert Atmosphere Soldering: Some solder machines incorporate inert atmosphere soldering techniques, wherein soldering occurs in a controlled environment devoid of oxygen. This prevents oxidation, resulting in superior solder joint reliability and performance.In traditional wave soldering processes, oxidation of solder joints can occur due to exposure to air, leading to poor wetting and weak solder connections. Inert atmosphere soldering eliminates this risk by creating a protective environment around the solder joint, ensuring pristine soldering results and enhancing product reliability.

3. Integrated Process Control Systems: Leveraging the power of automation, many solder machines are equipped with integrated process control systems. These systems monitor key parameters such as solder temperature, conveyor speed, and flux deposition, ensuring consistent and high-quality soldering results.Process control systems enable real-time monitoring and adjustment of soldering parameters, minimizing variations in solder joint quality and enhancing process repeatability. By maintaining tight control over soldering parameters, the solder machines ensure uniform soldering results across production batches, thereby reducing rework and enhancing product reliability.

Applications of Lead-Free Wave Solder Machines

1. Consumer Electronics: From smartphones to home appliances, the solder machines play a crucial role in the manufacturing of consumer electronics. Their ability to deliver reliable and environmentally sustainable solder joints makes them indispensable in this fast-paced industry.Consumer electronics manufacturers rely on the solder machines to meet stringent quality and reliability standards while minimizing environmental impact. By adopting lead-free soldering processes, companies can enhance the sustainability of their products and appeal to environmentally conscious consumers.

2. Automotive Electronics: The automotive sector relies on the solder machines to meet the rigorous performance and safety standards of modern vehicles. By ensuring robust solder connections, these machines contribute to the longevity and reliability of automotive electronic systems.Automotive electronics are subjected to harsh operating conditions, including temperature fluctuations, vibration, and moisture exposure. The solder machines provide the durability and resilience required to withstand these challenges, ensuring the reliable operation of critical vehicle components.

3. Industrial Equipment: In industrial settings, where electronic components are subjected to harsh operating conditions, the reliability of solder joints is paramount. The solder machines provide the durability and resilience required for industrial-grade electronic assemblies.Industrial equipment manufacturers rely on the wave solder machines to ensure the long-term reliability of their products in demanding applications such as manufacturing automation, power generation, and process control. By adopting lead-free soldering processes, companies can minimize the risk of solder joint failure and enhance the performance of their industrial equipment.

Challenges and Future Outlook

While lead-free wave solder machines offer numerous benefits, their adoption is not without challenges. The transition from lead-based to lead-free soldering processes may require retooling and retraining, posing initial hurdles for manufacturers. Additionally, the higher cost of lead-free solder alloys compared to traditional solder materials remains a consideration for budget-conscious companies.

Looking ahead, continued research and development efforts aim to address these challenges and further enhance the performance. Innovations in solder alloy formulations, process optimization techniques, and equipment design promise to unlock new possibilities in electronic manufacturing.

Conclusion

Lead-free wave solder machines represent a cornerstone of sustainable electronic manufacturing practices. By prioritizing environmental stewardship, worker safety, and regulatory compliance, these innovative devices are reshaping the landscape of the electronics industry. With ongoing advancements and a commitment to excellence, the solder machines are propelling us towards a future where technology and sustainability harmonize for the benefit of all.