メールフォーマットエラー

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

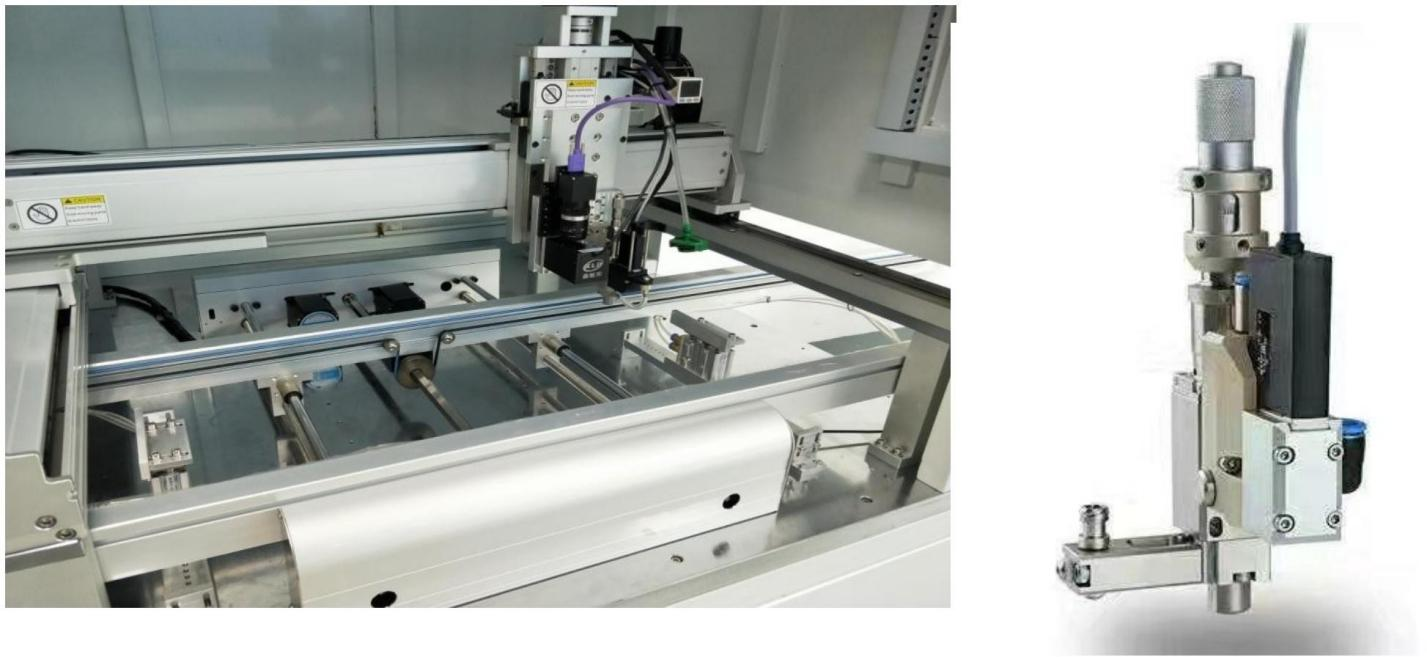

Revolutionizing Manufacturing: The Automatic Glue Dispensing Machine

In today's rapidly evolving manufacturing landscape, precision and efficiency are paramount. One technological marvel that is transforming production processes is the automatic glue dispensing machine. This groundbreaking innovation streamlines adhesive application, enhancing product quality, reducing waste, and boosting productivity. In this comprehensive guide, we delve deep into the workings, benefits, and applications of this game-changing device.

Understanding the Automatic Glue Dispensing Machine

The machine represents the pinnacle of precision engineering and automation. By leveraging advanced robotics and computer-controlled systems, this marvel of modern engineering applies adhesive with unparalleled accuracy and consistency.

Precision Engineering at Its Finest

At the heart of the machine lies its precision engineering. Equipped with high-resolution sensors and actuators, it ensures that the right amount of adhesive is dispensed with pinpoint accuracy. Whether it's a delicate electronic component or a rugged automotive part, this machine delivers flawless results every time.

Automated Efficiency

Gone are the days of manual adhesive application. With the machine, manufacturers can automate the entire process, eliminating human error and increasing throughput. This not only saves time but also reduces labor costs, making it a cost-effective solution for businesses of all sizes.

The Benefits of Using an Automatic Glue Dispensing Machine

The adoption offers a myriad of benefits across various industries. Let's explore some of the key advantages:

1. Enhanced Product Quality

Consistency is the hallmark of quality manufacturing, and the machine delivers just that. By ensuring uniform adhesive application, it eliminates variations in bond strength, resulting in products that meet the highest quality standards.

2. Waste Reduction

Traditional glue application methods often result in wastage due to over-application or uneven distribution. With precise control over adhesive flow, the machine minimizes waste, optimizing material usage and reducing costs.

3. Increased Productivity

Time is money in the manufacturing world, and the machine saves plenty of it. By automating the adhesive application process, it accelerates production cycles, allowing businesses to meet tight deadlines and fulfill customer orders promptly.

4. Versatility

From electronics and automotive components to medical devices and consumer goods, the machine finds application across a diverse range of industries. Its versatility makes it an indispensable asset for manufacturers seeking to stay ahead in today's competitive market.

Applications Across Industries

The versatility makes it a valuable asset in numerous industries. Let's explore how it's revolutionizing manufacturing processes across different sectors:

1. Electronics Industry

In the fast-paced world of electronics manufacturing, precision is non-negotiable. The machines play a crucial role in bonding components onto circuit boards with unmatched accuracy, ensuring optimal performance and reliability of electronic devices.

2. Automotive Sector

From sealing automotive assemblies to bonding interior components, the automotive industry relies on the precise application of adhesive for vehicle assembly. The machines streamline this process, enhancing product durability and safety while reducing assembly time.

3. Medical Device Manufacturing

In the highly regulated field of medical device manufacturing, consistency and precision are paramount. The machines enable manufacturers to adhere to strict quality standards, ensuring the integrity and reliability of medical devices used in critical healthcare applications.

4. Consumer Goods Production

From smartphones to household appliances, consumer goods manufacturers demand flawless aesthetics and robust construction. The machines facilitate the seamless bonding of components, enhancing the durability and appeal of consumer products.

Future Trends and Innovations

As technology continues to evolve, so too will the capabilities of the machines. Here are some emerging trends and innovations shaping the future of adhesive application:

1. Smart Integration

The integration of Artificial Intelligence (AI) and machine learning algorithms enables automatic glue dispensing machines to adapt to changing production requirements dynamically. Smart sensors analyze real-time data to optimize adhesive application parameters, further enhancing efficiency and quality.

2. 3D Printing Integration

The convergence of 3D printing and automatic glue dispensing opens up new possibilities in additive manufacturing. By combining precise adhesive deposition with layer-by-layer printing, manufacturers can create complex, multi-material objects with unparalleled precision and efficiency.

3. Eco-Friendly Adhesives

With growing concerns about environmental sustainability, the demand for eco-friendly adhesives is on the rise. automatic glue dispensing machines are adapting to accommodate these new materials, enabling manufacturers to reduce their carbon footprint without compromising performance.

Conclusion

The automatic glue dispensing machine stands as a testament to the transformative power of technology in manufacturing. By revolutionizing adhesive application processes, it enhances product quality, reduces waste, and boosts productivity across industries. As we look to the future, continued innovation in this field promises to redefine the possibilities of precision engineering and automation.