メールフォーマットエラー

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Linkage Conveyor

Linkage Conveyor

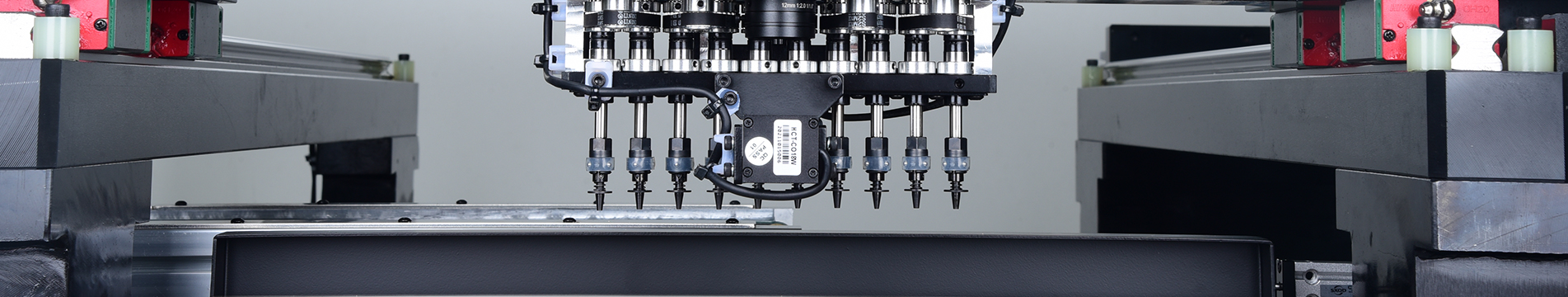

(1)In modern manufacturing processes, material handling plays a crucial role in the efficient and effective movement of materials and products from one production stage to another. The Linkage Conveyor is an automated conveyor system that has been designed to meet the demand for reliable and efficient material handling solutions. In this article, we will explore the features and benefits of the Linkage Conveyor, as well as its applications in different industries.

The Linkage Conveyor is a continuous conveyor system that uses a series of linked conveyors to move materials and products along a production line. It consists of a series of interconnected sections that are powered by a central drive unit. The system can be configured to suit specific production needs, with different section lengths, widths, and heights available. The Linkage Conveyor can also be integrated with other manufacturing equipment, such as robots and inspection systems, to create a fully automated production line.

One of the key benefits of the Linkage Conveyor is its flexibility. The system can be configured to meet the specific needs of a wide range of industries, from food and beverage to automotive and electronics manufacturing. It can handle a variety of materials, including heavy and bulky items, as well as delicate and fragile products. This versatility makes it an ideal solution for businesses looking to streamline their material handling processes.

Another advantage of the Linkage Conveyor is its reliability. The system has been designed to minimize downtime and reduce the risk of product damage or loss. The use of linked conveyors provides a smooth and even flow of materials, reducing the potential for jams or blockages. Additionally, the central drive unit ensures that all sections of the conveyor move at a consistent speed, minimizing the risk of product damage due to sudden starts or stops.

The Linkage Conveyor also offers improved efficiency and productivity. By automating the material handling process, the system reduces the need for manual labor, reducing costs and increasing production output. The conveyor system can also be programmed to operate at different speeds and with different cycle times, enabling businesses to optimize their production processes.

In terms of maintenance, the Linkage Conveyor is relatively easy to maintain. The modular design of the system allows for easy access to components for cleaning and maintenance. Additionally, the use of standard components and spare parts ensures that maintenance and repairs can be carried out quickly and efficiently.

SMT Conveyors can link the SMT PCB magazine loader unloader for SMT assembly, these PCB conveyors are mainly used for equipment linking, visual inspection, manual assembly, and PCB buffering functions. Their advantage is the short length, which allows them to be placed anywhere when you have space limitations. Durable HCT Linkage Conveyors link together your SMT assembly line. Place in between any assembly line machinery to transport your PCB safely from one machine to the next.

HCT provides high-quality industrial SMT peripheral equipment, we are a professional factory from China, that supports OEM. You are welcome to contact us.

SMT General Buffer Conveyor SMT Single / Dual Rail Conveyor

SMT Peripheral Equipment, Mass Soldering, Small Dip Soldering Machine, Pick & Place Machine, We take great pride in a great reputation among our customers for our exceptional product or service excellent, competitive rate, and also the best services. Today, We are with great passion and sincerity to further fulfill our global customers' needs with good quality and design innovation. We warmly invite clients from all around the world to build long-lasting business relationships that benefit both parties and look forward to a bright future together.